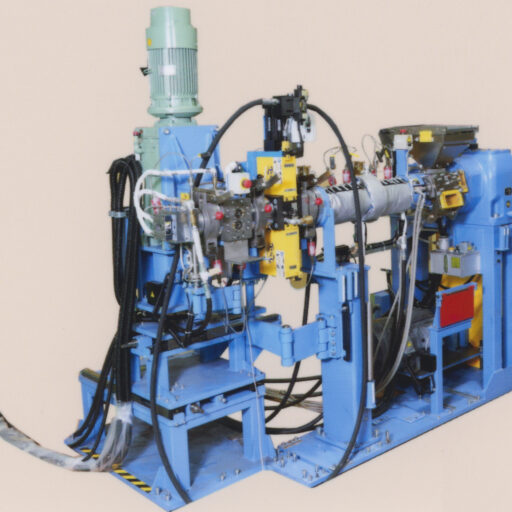

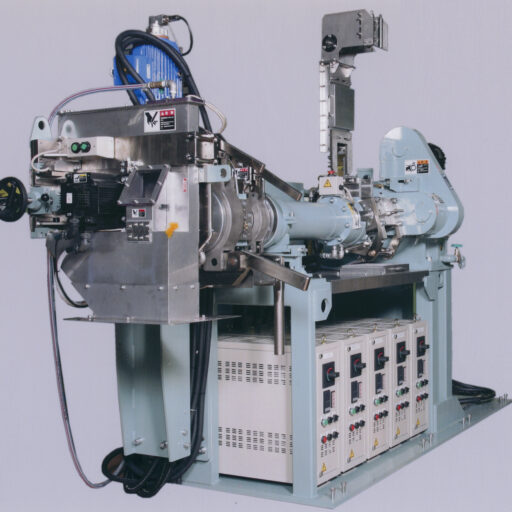

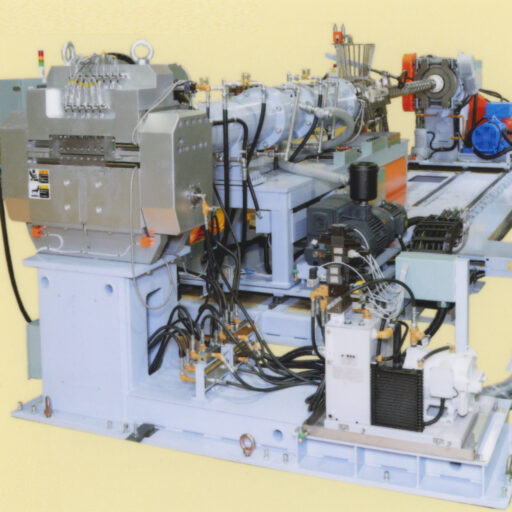

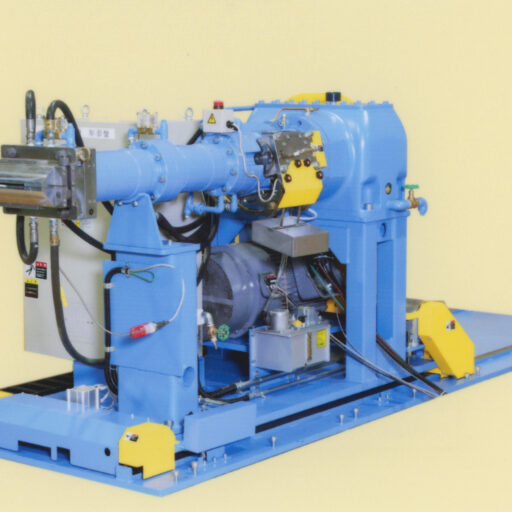

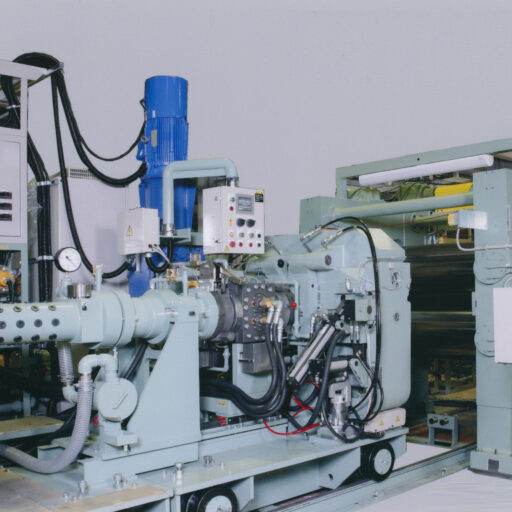

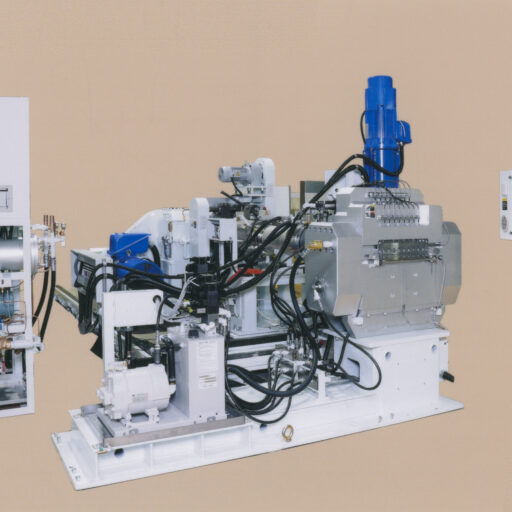

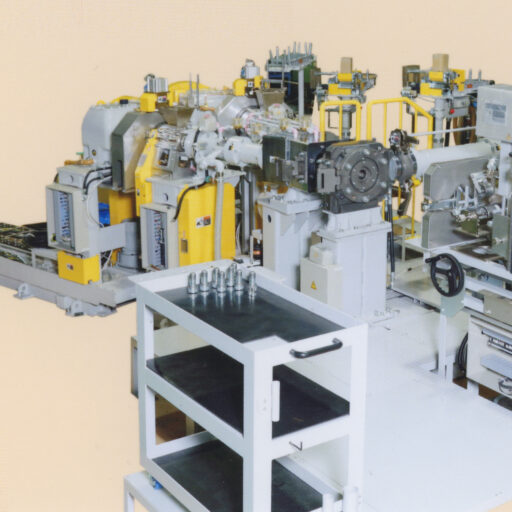

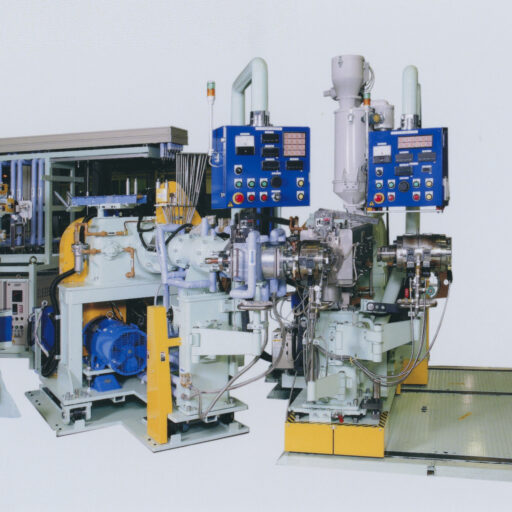

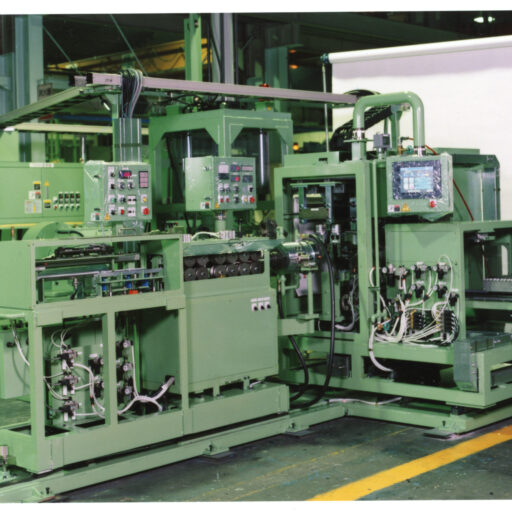

Rubber extruder

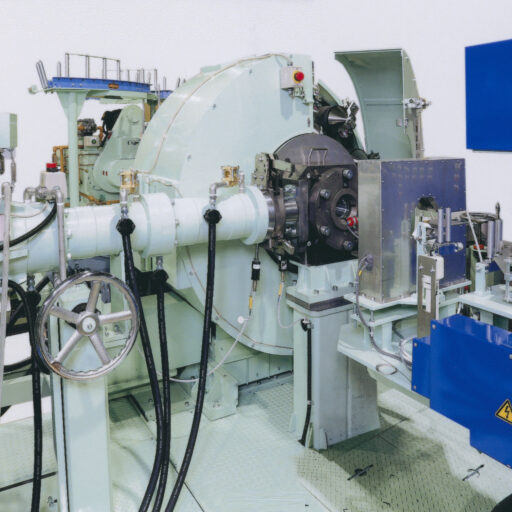

addition to its achievements and experience, we design screws and flow paths in-house based on material data that makes full use of measuring instruments such as Brabender viscometers and Capillary rheometers, and we also assemble in-house major parts with our own high-performance processing machines and skilled technicians.

Our extruders are used in a variety of fields, including automobile hoses and tires, construction sealants, medical tubes, power cables, and printing rolls.

Having small extruders like screw size φ20 mm to larger large extruders like φ200 mm, our extruders are used in various fields such as automobile hoses and tyres, building sealing parts, medical tubes, electric cables, and printing rolls and so forth. If advising us the application and specifications, we are glad to propose the most suitable equipment including front and rear equipment.

Product Features

Abundant Equipment Variations

We have even extruders from small size with a screw diameter of φ20 mm used for medical and laboratory use, to large size extruders with a screw diameter of φ200 mm or more for materials straining applications, tyres, vibration-proof products, and other products that require a big throughput extrusion.

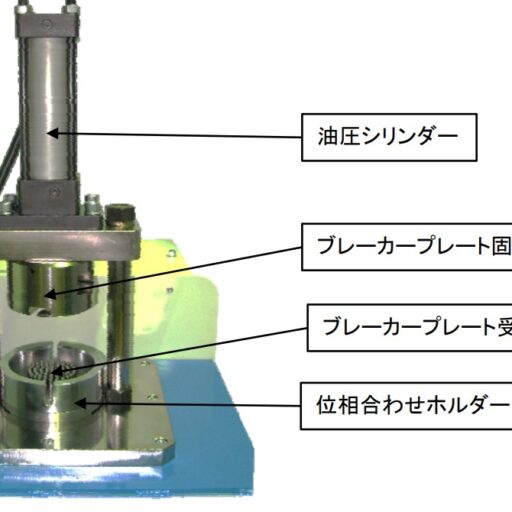

High Pressure Resistance Design

The pressure resistance of the Mitsuba Rubber Extruder is designed based on the regular use of 35MPa (MAX.50MPa) in consideration of the fact that it can be used for products where extrusion pressure is applied, such as hard rubber materials and small-diameter/thin-walled products.

If higher pressure resistance is required, it is also available in high pressure resistance type compatible with MAX.100MPa. (option)

Wear Resistant

Although it is an optional item, it is also possible to change the screw and liner (cylinder inner surface) to a special material as a measure against wear of materials mixed with metal powder such as carbon-rich materials and magnet rubber.

Note) Wear resistance does not mean that there becomes no wear, but that it has a longer life than standard materials.

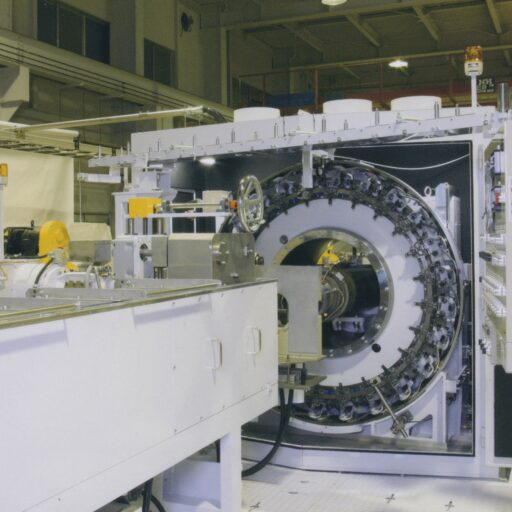

Abundant types of extrusion head

There is a wide variety of heads available depending on the manufacturing item and requirements, such as sheets, wire coatings, and multilayer heads.

The flow path design is also a custom-made product designed and manufactured in-house based on material data from measuring instruments such as Brabender viscometer and capillary rheometer.