Rubber Extrusion Equipment for Fenders and Vibration Dampers

Product Features

Extruder lineup with diverse variations and line auxiliary equipment

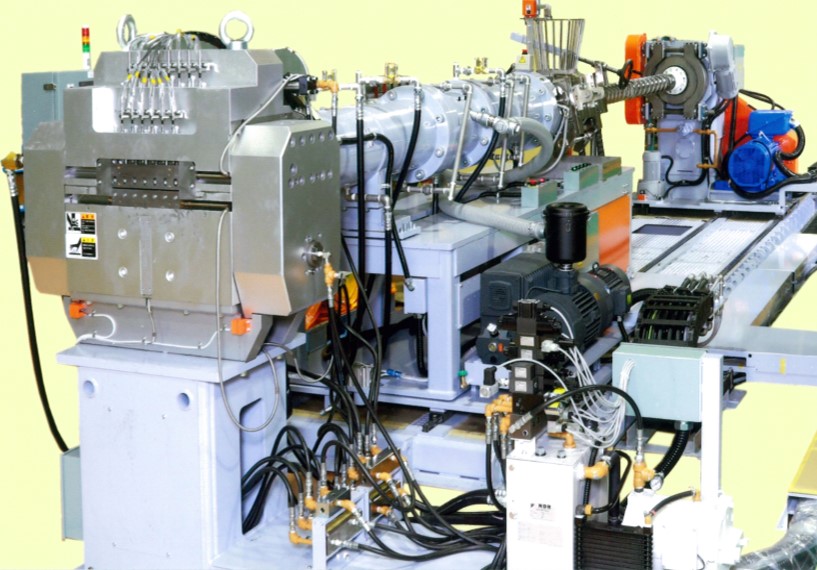

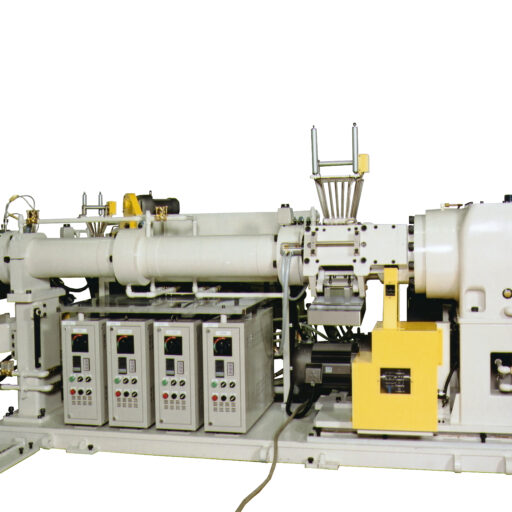

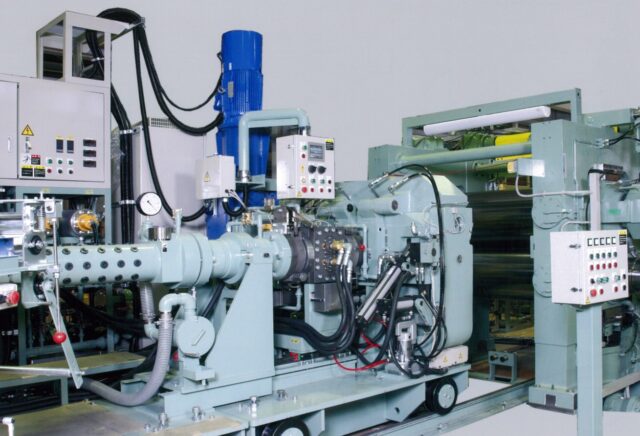

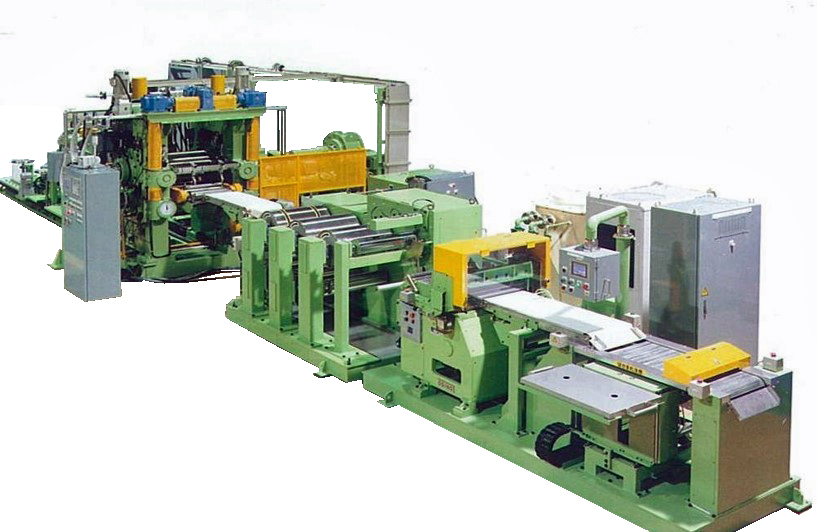

We offer a comprehensive range of extruders, including models featuring vent mechanisms essential for vibration-damping and seismic isolation rubber, extruders with pin-type cylinders for enhanced mixing performance, and pin-converter extruders, all with screw diameters up to 200 mm or larger.

We can provide proposals for complete lines including ancillary equipment such as calendering rolls, cooling tanks, cutting machines, and palletizing equipment for sheets after cutting, in addition to extruders.

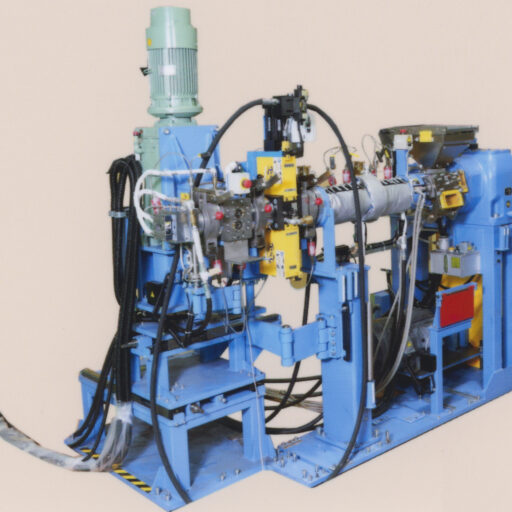

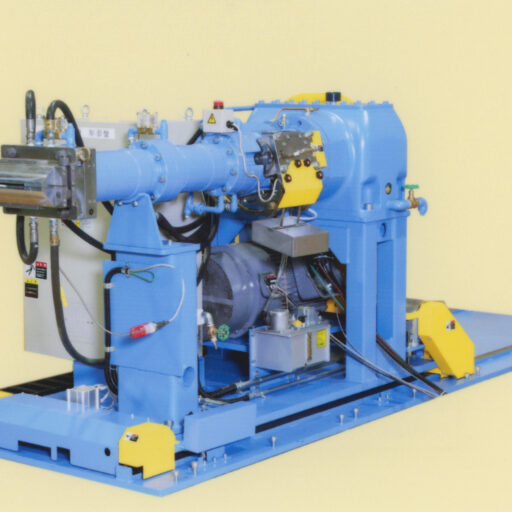

Improved Extrusion Stability and Reduced Extrusion Load Using Gear Pumps

Gear pumps, also known as positive displacement pumps, achieve stable extrusion volume by maintaining constant pressure at the pump inlet through pressure control.

It also suppresses heat generation in the rubber material caused by pressure on the extruder side, enabling extrusion at lower temperatures than when using the extruder alone.

This expands the screw rotation range of the extruder, enabling increased extrusion output.

※Extrusion volume may vary depending on extrusion conditions such as rubber material viscosity, head pressure, and rubber temperature.

Optional Features for Improved Setup and Cleaning Efficiency

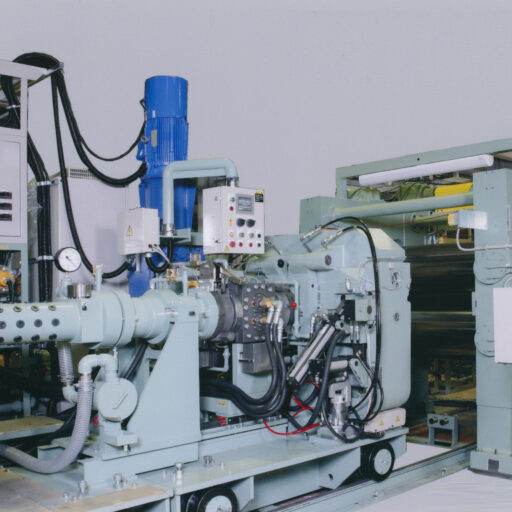

Hydraulic Opening/Closing Sheet Head

By using a hydraulic cylinder to open, close, and tighten, the need for removing and reinstalling clamping bolts, as required with conventional T-dies, is eliminated. This significantly reduces setup and cleaning times.

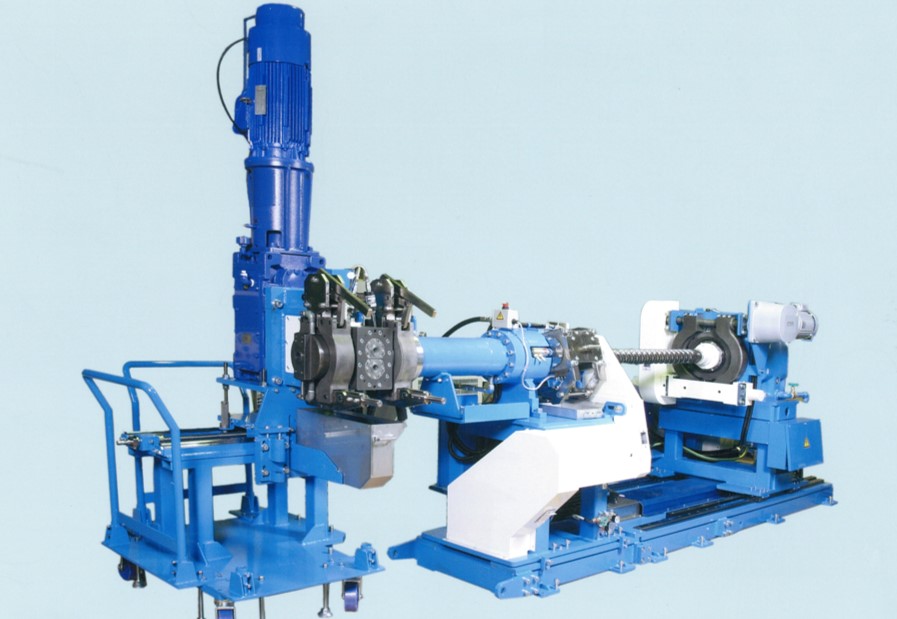

Gearbox Split Type Extruder

By adopting a split gearbox design, the screw can be retracted backward while remaining attached to the gearbox. This eliminates the need to remove the screw’s water cooling fitting, reducing extraction and reinstallation time to streamline operations.