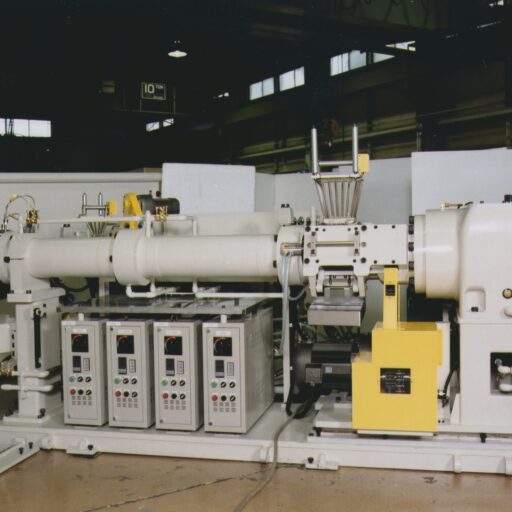

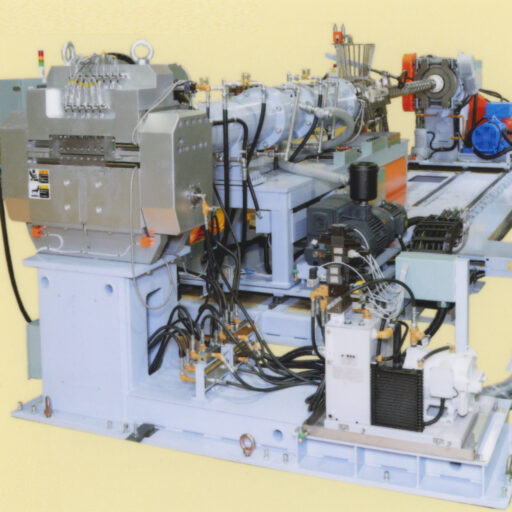

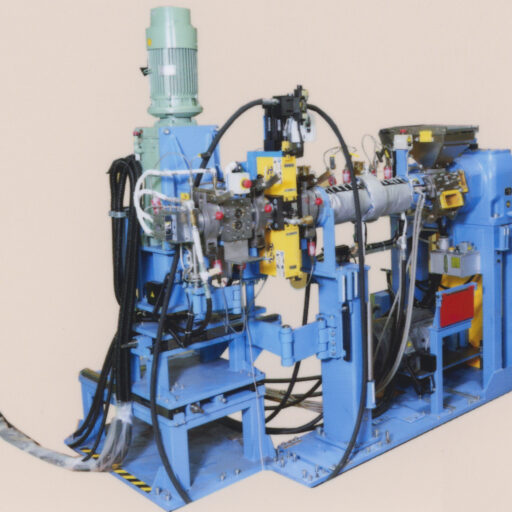

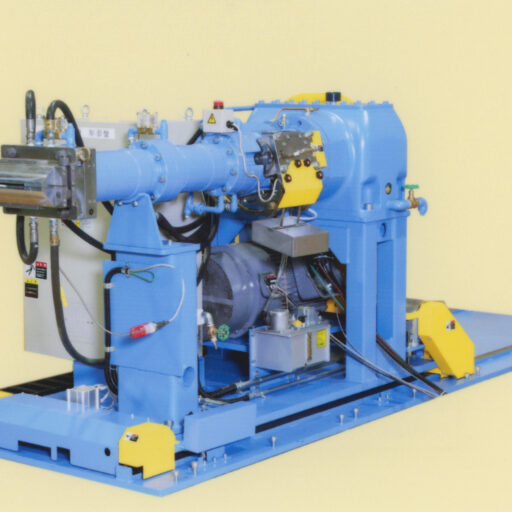

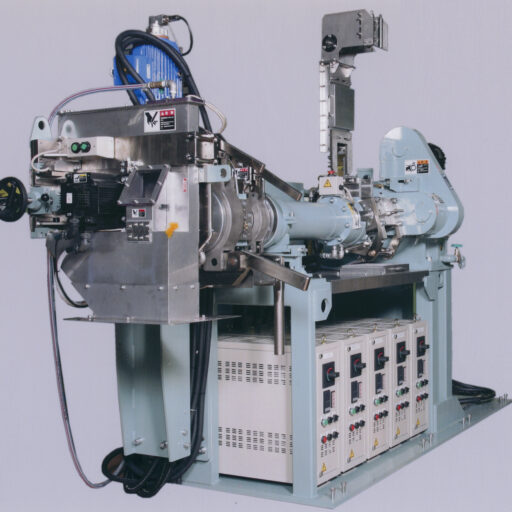

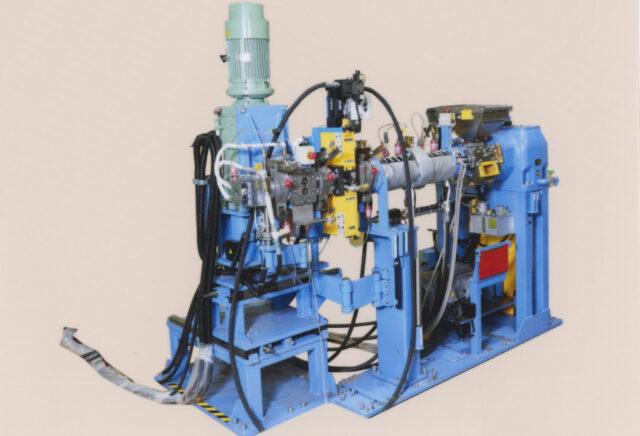

Gear Pump for Rubber

Mitsuba was one of the first to recognize the need for gear pumps, and has been selling rubber gear pumps originally developed since 2007.

We have a lineup of 18 models from low discharge to large discharge so that they can be used for various purposes.

In addition, based on our many years of sales performance, we are also working on improving cleaning and maintenance with reference to customer needs.

Product Features

1.Abundant line-up

We have a line-up of total 18 models, 9 models each of standard pressure type and high-pressure type.

We will propose the most suitable model according to the extrusion amount and application.

2.Bearings and seal ring

In the standard machine, the rubber material itself leaks from the bearing and play a role as a lubricant. If the type of rubber is sticky and difficult to clean, structure of bearing and seal ring can be changed to return the rubber from the outlet side to inlet side as an option.

3.Anti-wear treatment

Rubber itself acts as a lubricant, so depending on the type of rubber and the composition that contains a large amount of fillers, there is a concern that gear shafts, bearings, seal rings, and housings may wear out.

In such cases, we offer a wear-resistant type with a special coating. (Option)

4.Maintainability

The standard type has an integrated structure of housing. There is also a three-piece type in which the center part, which is heavily worn by the metal touch of the gear and the contact with the rubber, is divided.

This makes maintenance easier and reduces the cost of consumables. (Option)