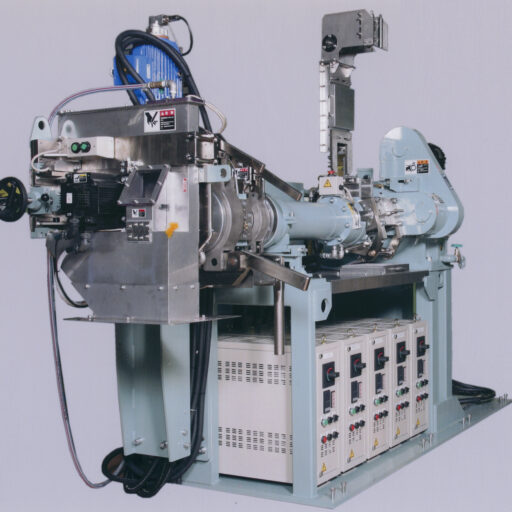

Unit Type Hot Water Circulation Unit

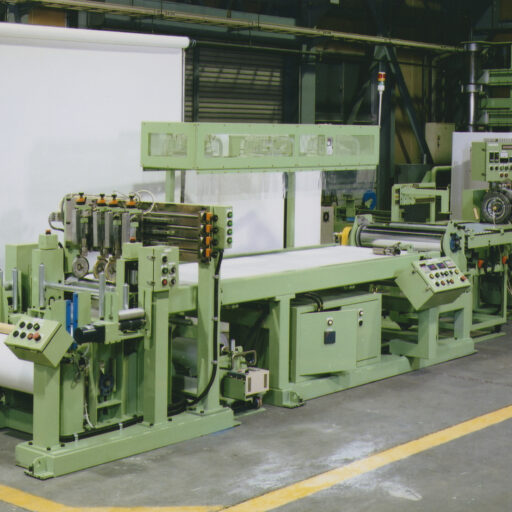

Therefore, we use a hot water circulation system to maintain the temperature of the materials at a constant level, thereby achieving both product quality and production volume.

Product Features

Stable Extrusion

Stabilizing the temperature of cylinder and screw is essential to suppress variations in the throughput.

In order to make it less likely to be affected by the shear heat generation of rubber and resin, we have devised to eliminate the temperature difference between the inlet and outlet of the cylinder or screw by increasing the flow rate optimizing the pump and piping size.

Temperature controller

RKC FZ-400 series is the standard temperature controller, but it can be changed to the same model used currently by customer, so you can share the spare parts.

Also, by changing to a temperature controller with communication function, remote operation can be performed on the touch panel of the operation panel even if a hot water circulation unit is installed on the back side of device due to layout restriction, and batch temperature setting can be made from the recipe management screen. They lead to improvement of workability.

Maintainability

Since the drainage port of the device body is provided on the bottom of the hot water tank, the heat medium can be completely discharged together with the impurities by using air purge together.

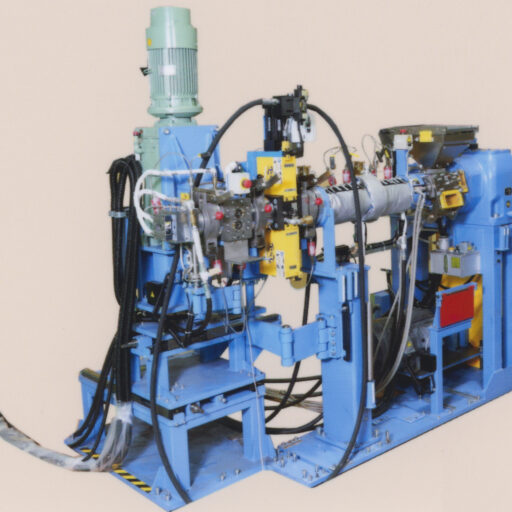

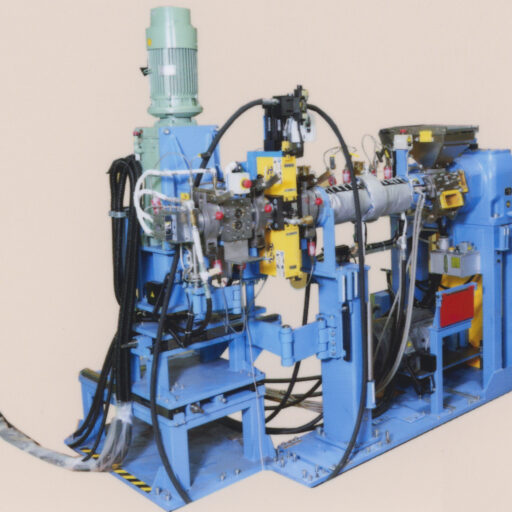

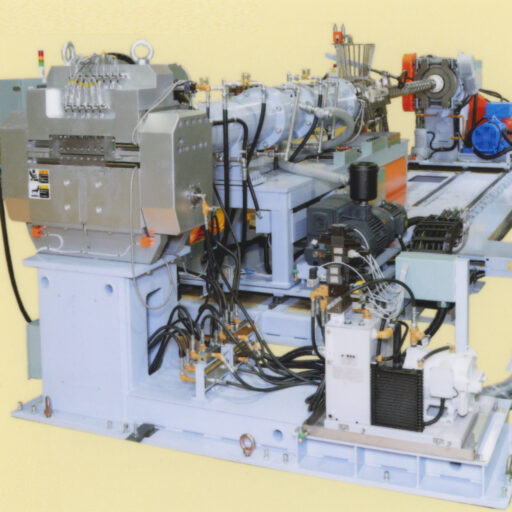

In addition, since each circuit is an independent unit type, even in the unlikely event of a failure, you can replace it with a spare unit and send it back to us for repair without stopping production.

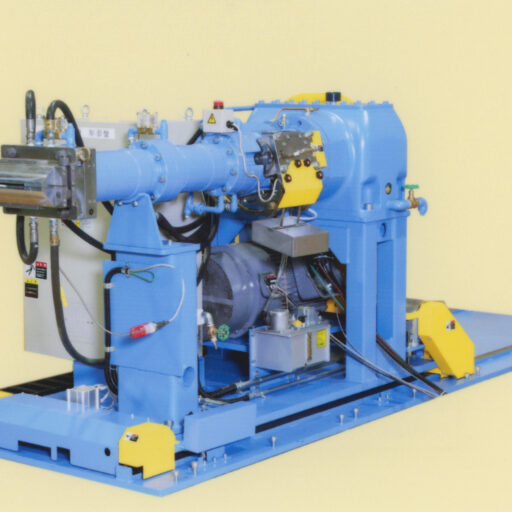

High Temperature Model Available

The general-purpose type NUT series has a maximum heating temperature of up to 95 ̊C, but we also have the NST series with a maximum heating temperature of 120 ̊C for use with fluoro rubber and materials mixed with resin compounds extrusion.

The NST series is equipped with a switch for switching between direct cooling and indirect cooling. Even during direct cooling, if the temperature of the heating medium exceeds 95 ̊C, it automatically switches to indirect cooling.

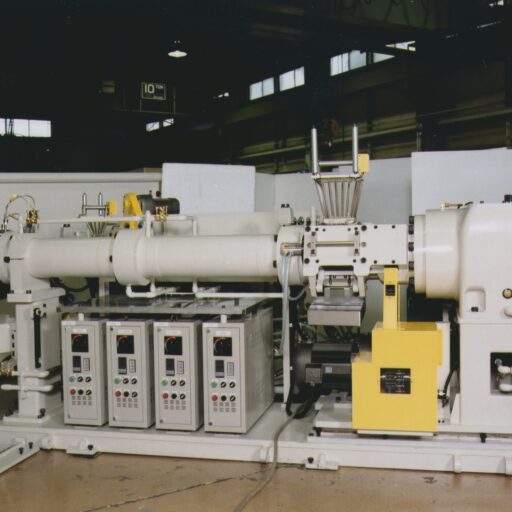

Flexible Layout

The body of the hot water circulation unit has a compact design that does not have wiring and piping parts on both sides by incorporating control parts. Therefore, it is possible to place according to the customer’s layout such as underneath extruder cylinder or separate installation.

notes: depending on extruder size and center hight