Corrugator(Corelco)

Reliability and performance are the most important factors in Corelco's extrusion molding.

Corelco's equipment is segmented according to various criteria, such as the diameter of the tubes it produces.

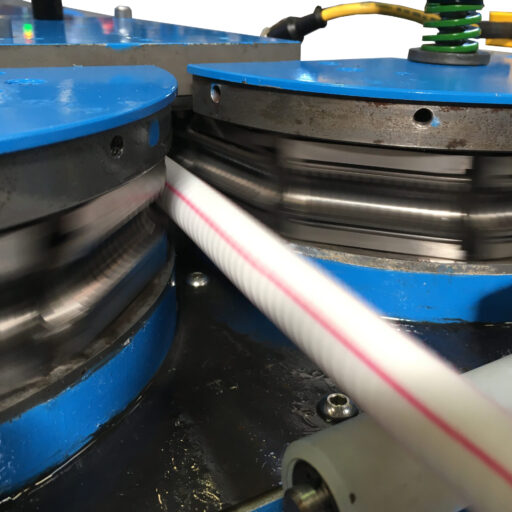

Vacuum technology with an indirect yet efficient cooling system enables low maintenance levels, high productivity, and controlled production.

Corelco's equipment is segmented according to various criteria, such as the diameter of the tubes it produces.

Vacuum technology with an indirect yet efficient cooling system enables low maintenance levels, high productivity, and controlled production.

Product Features

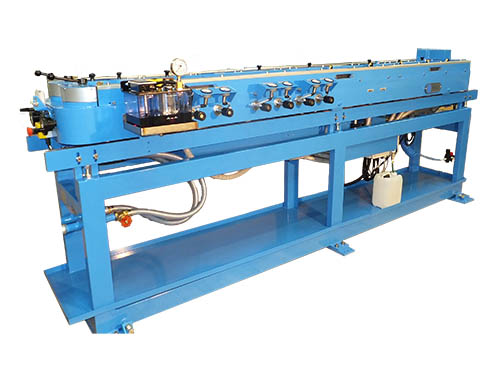

Corrugator Ø4 – Ø15mm

The Corrugator EC14 is specifically designed for small-diameter extrusion molding.

The Corrugator EC14 features a compact design that significantly reduces mold length and head pressure.

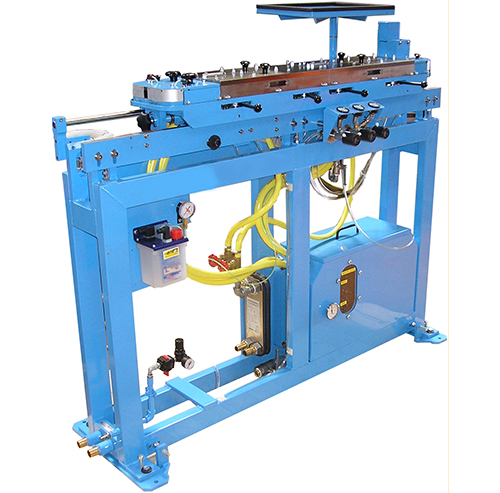

Corrugator Ø6 – Ø63mm/Ø40 – Ø250mm

This is a general design primarily targeting the electrical equipment market.

The three types of corrugators—EC32, EC50, and EC63—each have different production capacities.

Medium-speed, high-speed, and ultra-high-speed models offer varying production capacities and proven reliability.

We also have a proven track record in the automotive-related market.