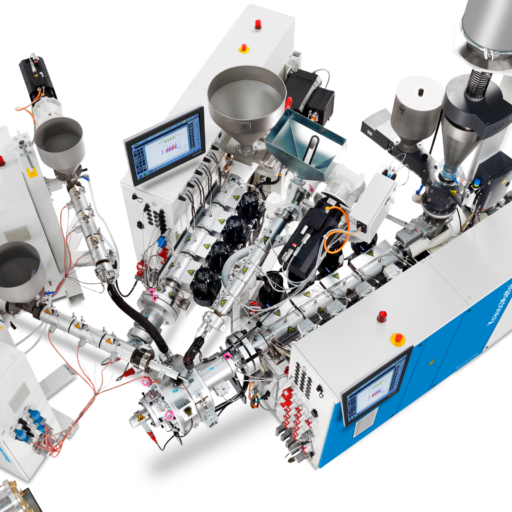

High Discharge Type Resin Extruder

Since basically using procurable machinery and electrical components in Japan, and customers can choose PLCs and other components made by manufacturers with which customers are familiar, you can use the equipment with peace of mind with regard to maintenance after delivery.

As we have test model, you can check how it move on request. (fare-paying)

Product Features

1.High throughput / low temperature extrusion

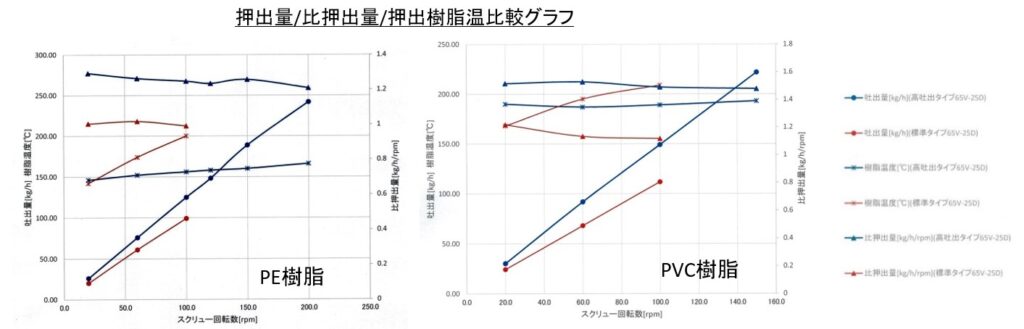

As the following graph shows, (Compared to our company’s products)

In addition, the effect of shear heating due to screw rotation is minimal, and since the screw can be used in a high rotation range, the total extrusion rate can be expected to be nearly twice that of the total extrusion rate.

※ There are differences depend on resin materials, extrusion size, extrusion pressure.

2.Increase production speed

Within the limited installation space of the extruder, it has the same throughput as a large extruder of one size-up or more, which leads to an improvement in production speed.

3. Material loss reduction.

Since it’s able to reduce the size of the extruder by one or two sizes with the same extrusion volume, reduce the amount of material remaining in the cylinder during material and color changes, which is expected to improve running costs.

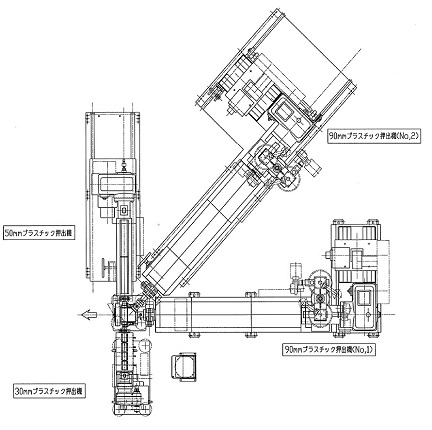

4. Space saving

Due to extruder can be downsized, increasing latitude of deployment layout when 2 or 3 layer extrusion and it enable joint part shorten. Then improve cleanability and resin burning.

5. Maintainability

Since basically using machinery and electrical components made in Japan, there is no interfere about parts procurement in case of breakdown. In addition, due to hardware and software are in-house design, and customers can choose PLCs and other components made by domestic manufacturers with which customers are familiar, easy to link with lines of your factory.

6.Abundant size variations

We have a variety of screw diameters from φ65mm to φ150mm, so we can offer a wide range of sizes to suit your extrusion volume and application.