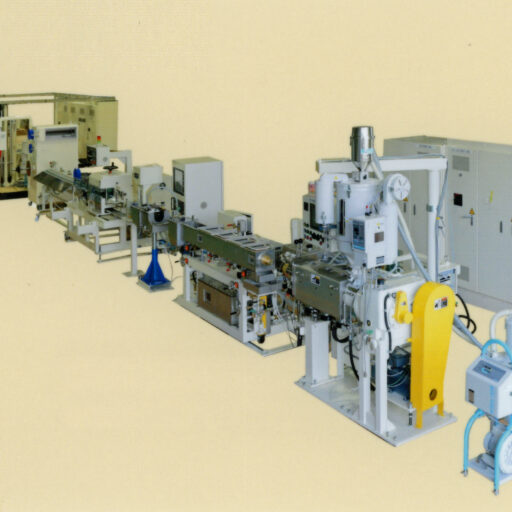

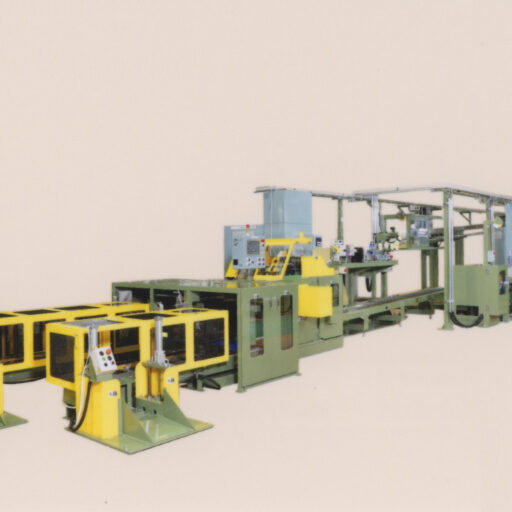

Fluororesin Extruder

As a counter-measure to prevent contamination due to corrosion of fluorine gas, Mitsuba's fluoro-resin extruder has corrosion-resistant measures not only for the corrosion-resistant material of the flow path, but also for all other details.

※The temperature control zone structure has been reviewed to improve throughput stability.

Product Features

1. Extruder size variations

It is available each size from the minimum screw size φ14 mm to φ50 mm.

Note: Since screw size more than φ 50 mm have material restriction please contact us separately.

2. Corrosion Measures vs Fluorine Gas

Corrosion-resistant metal is naturally used where the resin comes into direct contact, such as the cylinder, screw, and head. In addition to that, we have taken measures against corrosion in every detail, such as devising methods to prevent backflowing fluorine gas from entering the inside of the cylinder through the gap in the hopper.

3. Shell Clamp type Head Connection

The extruder and head are connected using a manual shell clamp as standard. Since the shell clamp method is tightened so as to wrap the entire circumference of the flange evenly, resin leakage due to one-sided tightening is prevented compared to the conventional 4-bolt method.

Note: Please note that the shell clamp is a consumable item to maintain its strength and to prevent corrosion only with nickel-based plating.