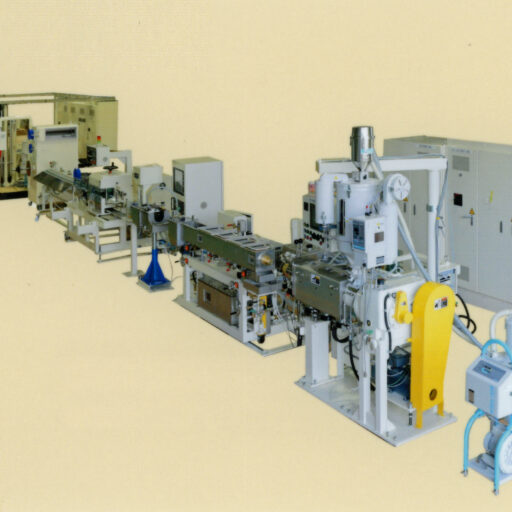

Sizing Water Tank

Calibration Water Trough is essential for current manufacturing field such as increasing products that tubes and hoses required strict dimension accuracy.

Our calibration water trough designed for various materials from general resin like polyethylene to special resin such as fluororesin, polyurethane and polyamide.

OD calibration systems that reduce the pressure inside the trough by means of vacuum pump enable the stable production of both hard and soft tubes with precise dimensions and roundness, especially when combined with circulating water with a high cooling effect and other options.

We have various type trying to accommodate customer's demand: From high accurate stability type by means of our original vacuum pressure control system which fluctuation between low vacuum pressure and high vacuum pressure fall within the ±0.1kPa to budget version that lower vacuum pressure accuracy and yet can stable control.

The OD calibration system by means of reduced pressure inside the trough features two compartments that enable the partitioning of the operation into weak vacuum and strong vacuum chambers.

Our calibration water trough designed for various materials from general resin like polyethylene to special resin such as fluororesin, polyurethane and polyamide.

OD calibration systems that reduce the pressure inside the trough by means of vacuum pump enable the stable production of both hard and soft tubes with precise dimensions and roundness, especially when combined with circulating water with a high cooling effect and other options.

We have various type trying to accommodate customer's demand: From high accurate stability type by means of our original vacuum pressure control system which fluctuation between low vacuum pressure and high vacuum pressure fall within the ±0.1kPa to budget version that lower vacuum pressure accuracy and yet can stable control.

The OD calibration system by means of reduced pressure inside the trough features two compartments that enable the partitioning of the operation into weak vacuum and strong vacuum chambers.

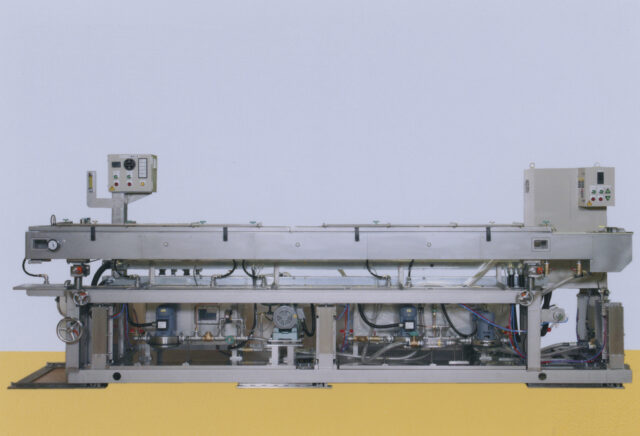

Product Features

- Control is applied to maintain constant low vacuum pressure, achieving highly precise dimensions.

- At a vacuum pressure setting of -20 kPa, cooling water flow rate of 40 L/min, the fluctuation of vacuum pressure is within ±0.1kPa.

- Even at a strong vacuum level of -40 kPa, fluctuation is kept within ±0.1kPa by means of vacuum control.

- Depending on the type of polymer used, the vacuum chamber is partitioned into a weak vacuum compartment to reduce the resistance of calibration, and a strong vacuum compartment for maintaining a stable OD and roundness to form the tube.

- The cooling system is also matched to the type of resin used by adopting the optimal method from a range of choices such as water immersion or spray, hot water system, etc.

- Effectiveness of cooling can be further enhanced in combination with a chiller unit.