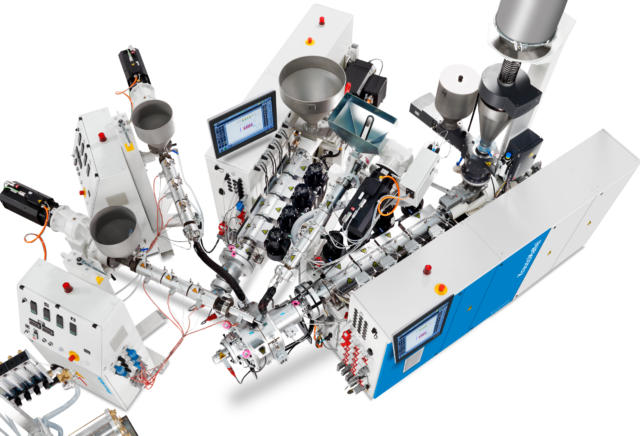

Pipe Extrusion Lines

KraussMaffei product portfolio covers single-screw extruders, counterrotating and corotating twin-screw extruders with corresponding pipe heads and downstream components through to fully automated pipe lines, processing

PVC or PO, for producing plastic pipes from 5 mm to 2500 mm in diameter - including automation components consistently engineered to maximize savings on materials, energy and costs, without compromising on product quality.

PVC or PO, for producing plastic pipes from 5 mm to 2500 mm in diameter - including automation components consistently engineered to maximize savings on materials, energy and costs, without compromising on product quality.

Product Features

- The QuickSwitch system for in-line dimension can be used to change the pipe dimensions during continuous production-simply at the push of a button. This effective and intelligent technology generates potentially enormous savings.

- With the aid of IPC technology, you can not only cool the outside of the pipe with water in vacuum tanks and cooling baths, but also cool the inside of the pipe using air, shortening the cooling section by up to 40 percent reduces both investment costs and space requirements.

- Large quantities of raw materials can be saved by keeping pipe diameter and wall thickness within tight tolerances. This can be achieved only by employing a sophisticated C7 control system capable of measuring and regulating the entire extrusion line.