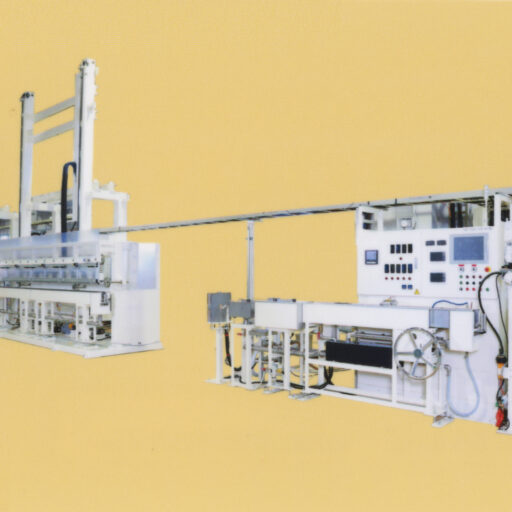

Flat-Square Wire Covering line

Each company working hard to develop the flat wire used in motor coils coated with an insulating layer: improve electrical resistance, heat resistance, and strength, the flat wire industry is expected to continuing great demand.

Mitsuba's flat wire coating line providing ingenious equipment as the system is mainly equipped with extruders corresponding to super engineering plastics such as PPS and PEEK resins, and is designed to coat micron-order coatings without running out of resin.

Product Features

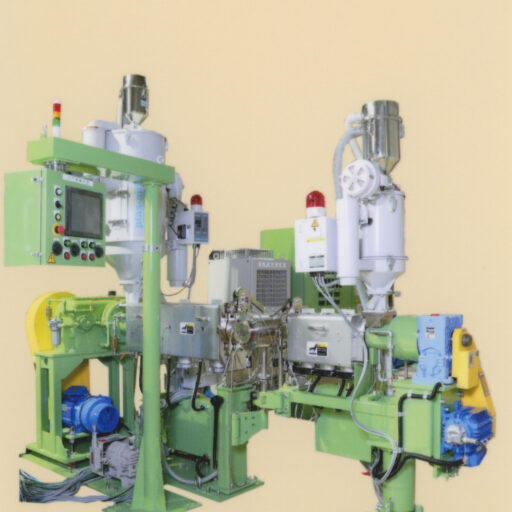

1. Plastic Extruder

We have a lineup of small-diameter extruders with screw diameters from φ14 mm to extrude resins with coating thicknesses of 100 μm or less with high discharge accuracy. We corresponding to customer demand by designing individual products according to the characteristics of the resin used, such as screw and cylinder materials, depending on the cylinder heating temperature and extrusion torque.

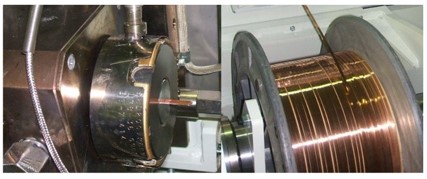

2. Crosshead

To coating entire circumference of flat line with uniform thickness, the flow path of crosshead is designed based on resin viscosity data.

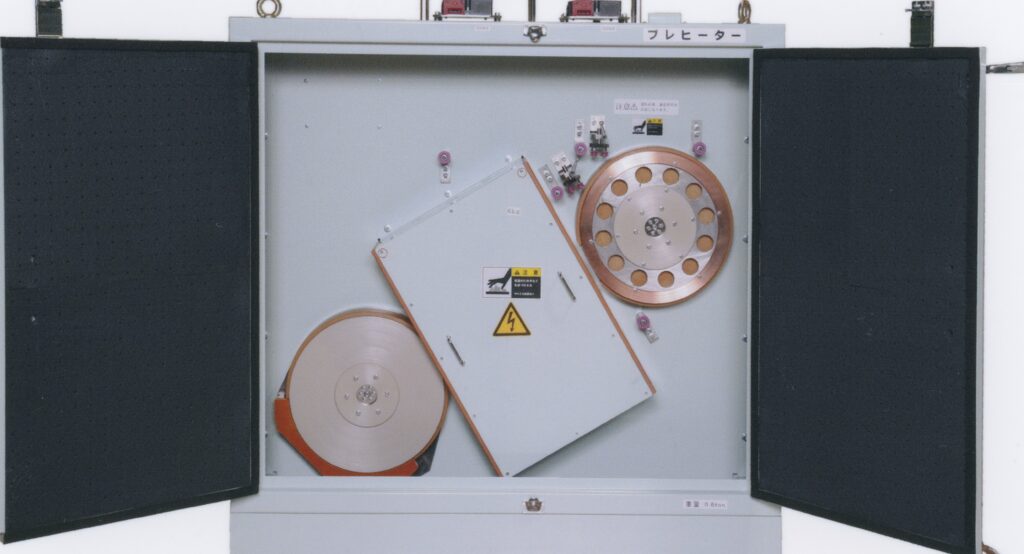

3. Warm up equipment (Pre-heater)

We think it’s not too much to say that pre-heater heating flat conductor before coating is indispensable item of this line, to thin-coating without running out of resin.

Depending on the cross-sectional area and radius of curvature of the conductor, we offer two types of preheating equipment: an induction heating type preheater using our self-developed electric resistance and an electric heating furnace type using radiation heat from the heater.

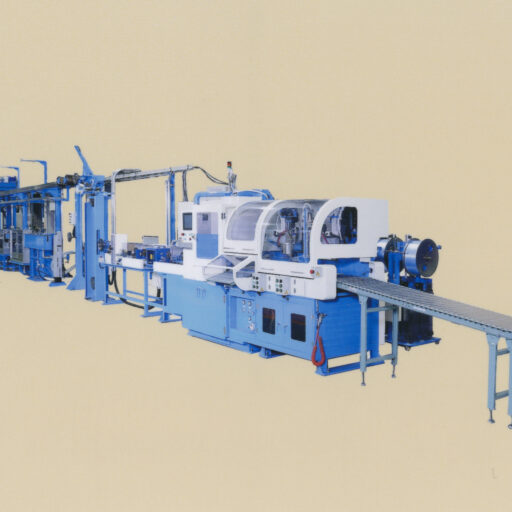

4. Removal twist and bend measures

In order to ensure that the flat rectangular conductor with a waist can pass through the crosshead without getting caught, we have adopted a straightening machine to remove bends in the wire feed drum and a drum traverse type supply stand to ensure that the conductor passes through the crosshead straight and true.

In order to ensure that the flat square conductor passes through the crosshead without twisting or twisting

traversing drum.

Equipment to correct winding in the wire feed drum.

After coating, we recommend a drum traverse type winder as well as a staggered type accumulator or a supply machine in order to wind the flat wire neatly on a drum without twist or torsion.

The addition of an accumulator allows for continuous operation as a production machine.

Accumulating wire with horizontal arrayed movable pulley without torsion wire.

Automatic winder exchanging drum without operator.