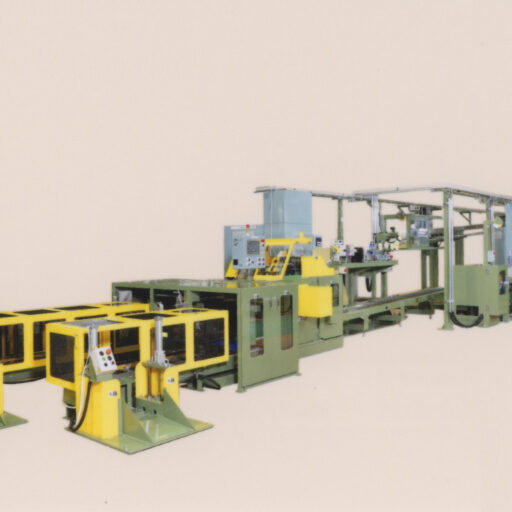

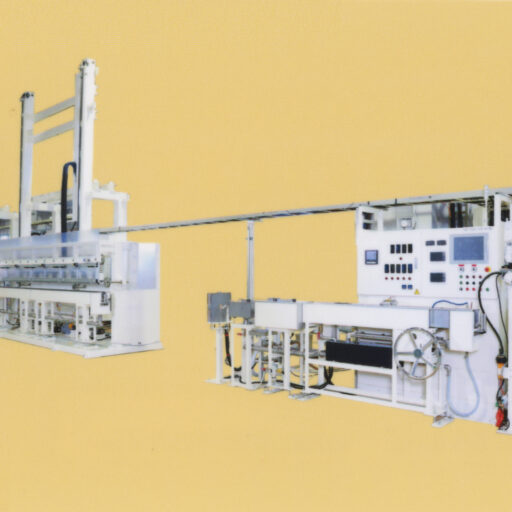

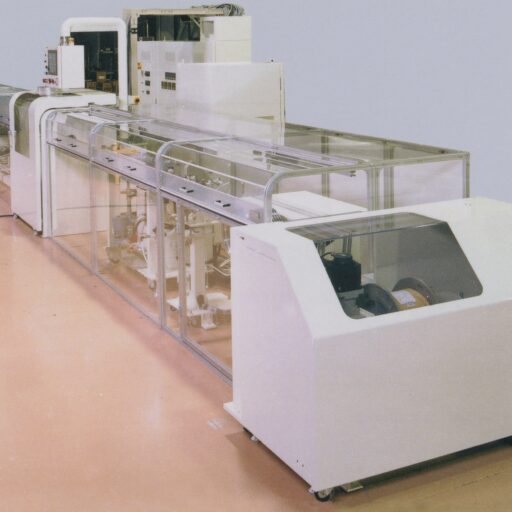

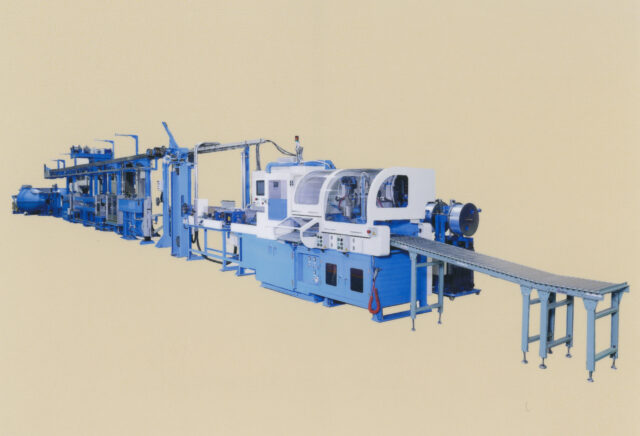

Automotive Cable Line

This equipment is a production line for automotive cables that use aluminum as the conductor.

・Applicable conductor diameter (cross section area): 0.75 sq ~ 1 2sq

・Production speed: MAX.1200 m/min

・The automatic coiling & tying device uses a compact tying head developed and manufactured by our company, and a tension stand is installed to coil the cable at a constant tension level.

・Furthermore, two types of supply stands, a dual hood wire feeding system and a payout system, are deployed, to enable the production of both large and small cables, in addition to installing three extruders, each dedicated, respectively, to a different range of cable diameters.

・Applicable conductor diameter (cross section area): 0.75 sq ~ 1 2sq

・Production speed: MAX.1200 m/min

・The automatic coiling & tying device uses a compact tying head developed and manufactured by our company, and a tension stand is installed to coil the cable at a constant tension level.

・Furthermore, two types of supply stands, a dual hood wire feeding system and a payout system, are deployed, to enable the production of both large and small cables, in addition to installing three extruders, each dedicated, respectively, to a different range of cable diameters.

Product Features

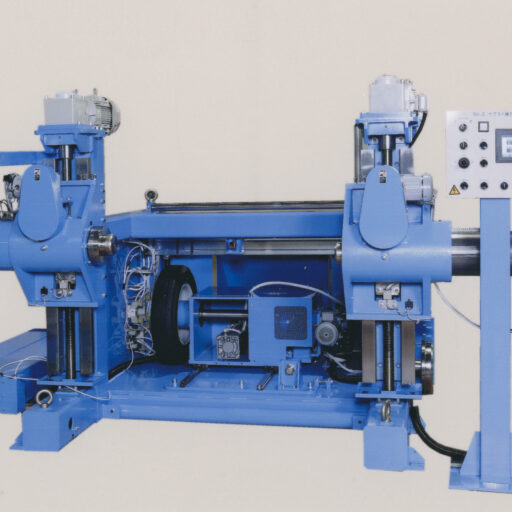

1.40mm Plastic Extruder

- For position adjustment with 60mm and 90mm resin extruders, it comes with a manual movement mechanism back and forth and left and right.

(Can be connected to either 60mm or 90mm resin extruder)

Moving length back / forth:1104mm

Moving length left / right :1300mm

Moving length back / forth :±20mm(By jack-up bolt)

- Comes with a pressure gauge and overflow valve on the head flange.

- The cylinder part is heated by an aluminum cast heater. (3 circuits)

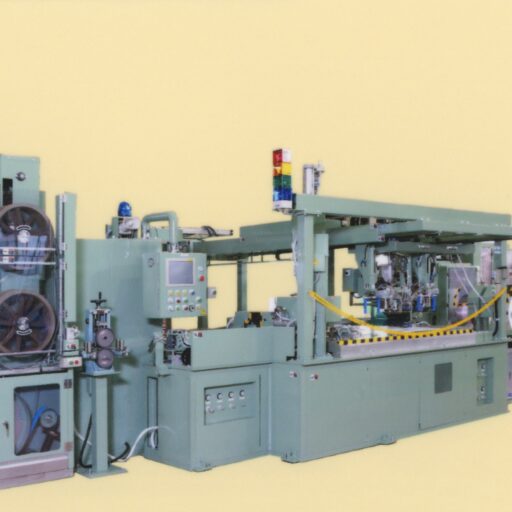

2.60mm Plastic Extruder

- Comes with a pressure gauge and overflow valve on the head flange.

- The extruder is movable back and forth using a manual handle (travel distance 500 mm)

- The cylinder part is heated by an aluminum cast heater. (4 circuits)

3.90mm Plastic Extruder

- Comes with a pressure gauge and overflow valve on the head flange.

- The extruder is movable back and forth using a manual handle (travel distance 70000 mm)

- The cylinder part is heated by an aluminum cast heater. (4 circuits)

4.Crosshead

5.Preheater

- Depending on the wire diameter, you can choose from two types: induction heating type and electric furnace.

① Induction Heating Type preheater

the line heating speed is controlled from the line speed

② Electric Heating Furnace Type Preheater

As a preheater for sheath cables, fiber cables, and thick cables that cannot be used with induction heating type

furnace heats the surface of the conductor directly by passing it through an electric furnace, is suitable for thin wires

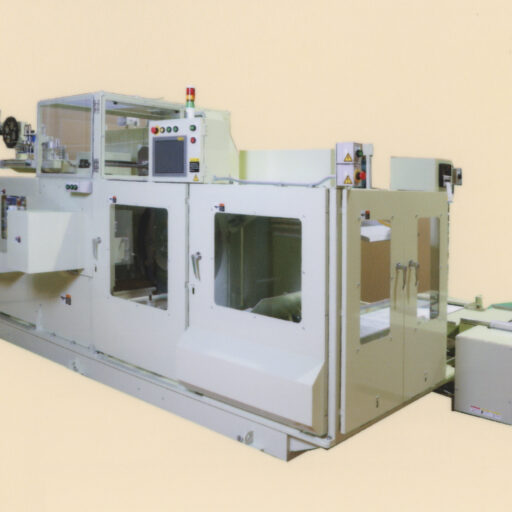

6.Coiling Machine

- Since two compact tying devices can be installed, tying at two locations at the same time will improve the production speed.

(Based on our actual results, the bundle length is 100 m, the line speed is 260 m/min when bundling at two locations)

- By adopting an electronic traverse, you can freely set the temporary stop of the turn position, the winding start position, the descending/ascending pitch, etc. on the touch panel, so you can wind under the optimal conditions according to the characteristics of the cable.

Also, by managing the recipes that have been set, you can shorten the setup time and reproduce the bundle appearance regardless of the skill of the operator.

- Since it can be tied according to the position of the winding start end and the termination, it is possible to prevent problems such as long protruding cables damaging the shrink wrap in the next process, or the cables getting caught during transport and stopping the line. You can also adjust the extra length of the PP band. By making the extra length longer, it becomes easier to manually remove the PP band without using tools such as scissors and will improve the next process work.