Intelligent Solution for Composite Pipe Systems

Intelligent Solution for Composite Pipe Systems

Product Features

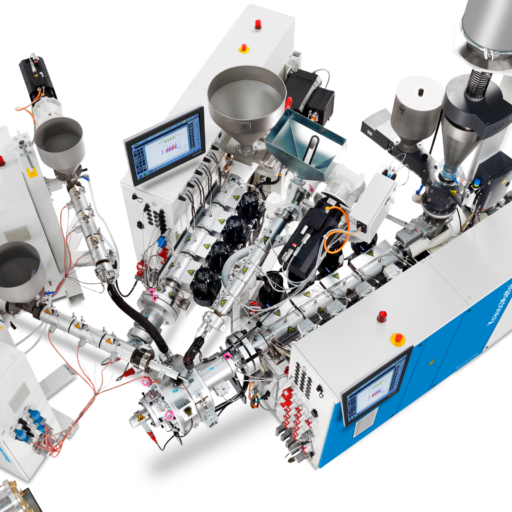

Combination of multi-layer extruders for multi-functions:

- For manufacturing multi-layer pipes, a complete manufacturing in-line system allows modular construction of multi-layer pipe heads for flexible and efficient manufacturing.

- Material distribution is performed via a coaxial spiral distributor. We have an option of using multi-layer adapters without shifting the coextruder to produce a thin outer layer. This adapter can be mounted directly to the standard pipe head to the nipple and die connections without any problems. The use of these multi-layer adapters enables single-layer, two-layers or more in forming outer layers

- With a slight modification of the contour flow, almost any material (including adhesives, EVOH, and PP) could be molded into a uniform layer, while using a double strip adapter it can be changed to make colored strips at the same time.

- The excellent cost-effectiveness of polyolefin pipe heads is realized by the optimal complementary advantages of both production and processing technology

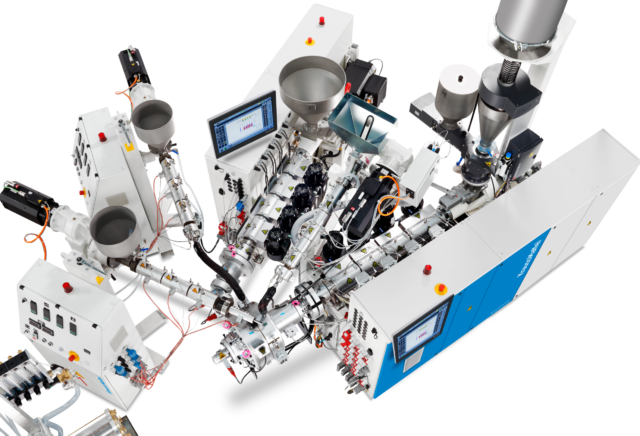

Material cost reduction by producing PVC with containing high volume of clay :

- High volume of clay formulation makes it possible to save raw materials and ensure product quality: Using 36D series of twin screw extruder. In the competitive PVC pipe market, producers are currently under constant pressure from rising prices. In particular, there is a tendency to use as high a proportion of filler as possible not only in drainage pipes but also in pressure pipes.

- By blending high volume of clay for suppressing price increase, high throughput rate is also attained while maintaining perfect product quality.

- Blending with a high proportion of clay (up to 60 parts) requires a fairly high energy input and is optimized by a long effective preheater. The 36D series twin-screw extruder has successfully cleared the optimization with this processing technology.

- The extruder has a horizontal and vertical weighing device so that it could process formulations with a high proportion of clay (more than 30 parts).

- The 36D machine concept ensures that PVC compounds are absolutely safe materials in normal and high filling degassing.