Rubber Sheet Production Line

For extruders as well, we can offer optimal proposals that meet your needs, such as non-vent type, vent type, pin type, pin convert type, and gear pump combination type.

Product Features

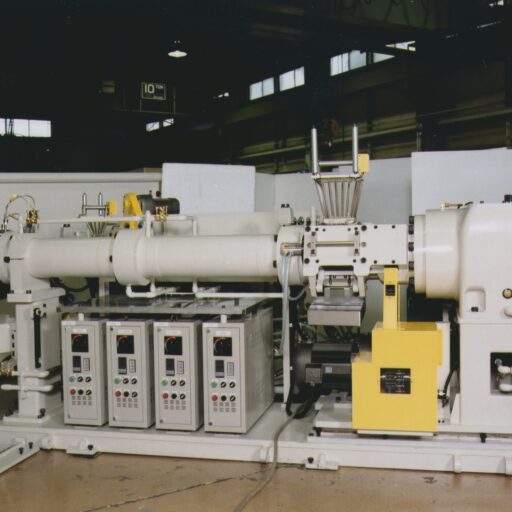

Rubber extruder

Abundant Product Composition met applications and needs you have!! The rubber extruder, which is one of our signboard products of Mitsuba Manufacturing Co., Ltd. has been adopted by many users both in Japan and overseas, with nearly 100 extruders annually since its establishment.

addition to its achievements and experience, we design screws and flow paths in-house based on material data that makes full use of measuring instruments such as Brabender viscometers and Capillary rheometers, and we also assemble in-house major parts with our own high-performance processing machines and skilled technicians.

Having small extruders like screw size φ20 mm to larger large extruders like φ200 mm, our extruders are used in various fields such as automobile hoses and tyres, building sealing parts, medical tubes, electric cables, and printing rolls and so forth. If advising us the application and specifications, we are glad to propose the most suitable equipment including front and rear equipment.

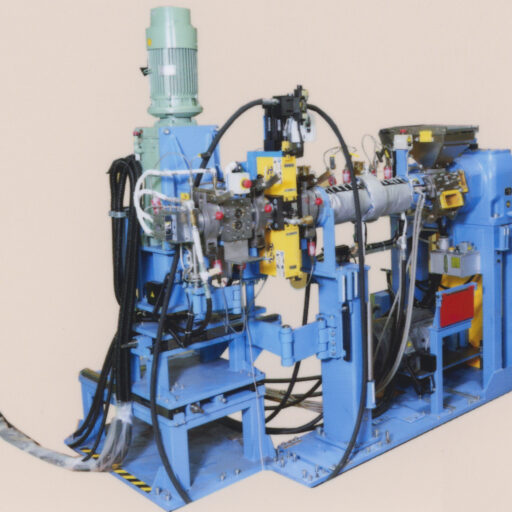

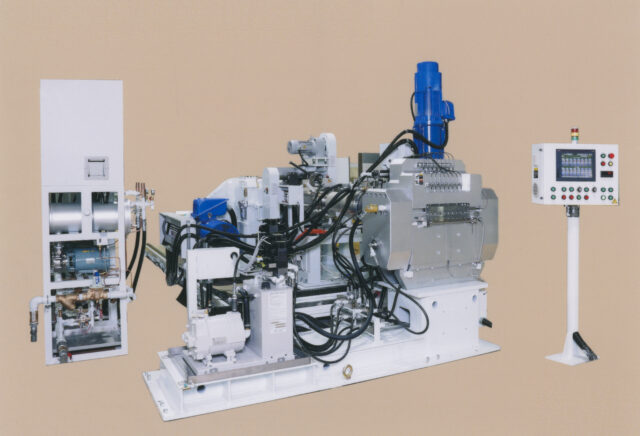

Pin Type Rubber Extruder

Concerning the pin type extruder, dozens of pins are projected from the cylinder toward the center of the screw, and the flight part of the screw is grooved in the circumferential direction so as to avoid interference with the pins which allow the pins to pass through.

And also, it have advantages that can discharge relatively low shear rate.

Pin-Convert Type Rubber Extruder

Concerning the Pin-Convert Type Rubber Extruder, dozens of pins are projected from the cylinder toward the screw, and the cylinder has Pin-Convert zone.

The Pin-Convert zone has a throttle section, the projected pins can be adjusted their length in the cylinder by manual or hydraulic cylinder. Pin-Convert allows the cross sectional area of the liner groove to be varied.

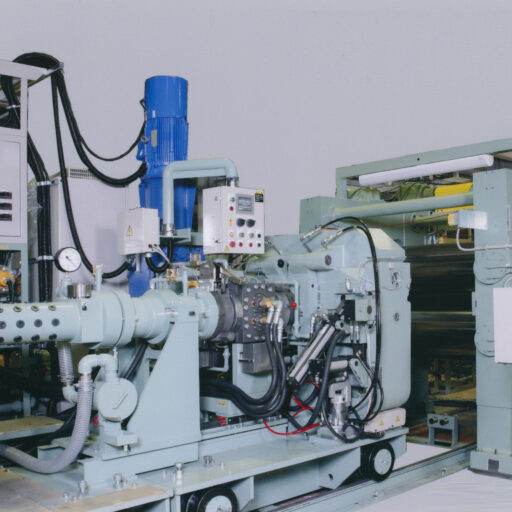

Rubber Extruder with Gear Pump

Since the rubber extruder performs the functions of transporting, heating, kneading, and weighing with screws, it can low temperature and stable high discharging compare to rubber extruder alone.

By combining with a gear pump, the discharge is stabilized in a shorter time than when the extruder is used alone, so material loss can be reduced.

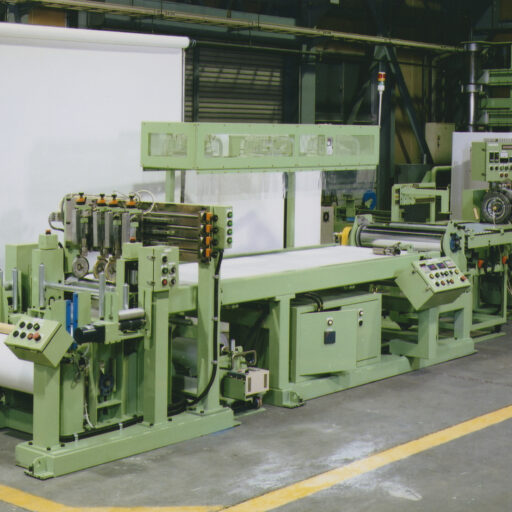

Roller Head Method

・By combining a calender rolls and a sheet take-out head, it is possible to produce rubber sheets with high thickness accuracy.

・As for the thickness of the rubber sheet, it is possible to produce sheets of several thicknesses by adjusting the calender gap without changing the die.

It costs higher capital investment than other method due to high-priced calender rolls.

Sheet Ejection Head Method

Since the product is extruded only with the sheet ejection head, it can be introduced with a lower capital investment than the roller head method. Using a hydraulic cylinder to open and close the head makes it easy to clean inside the head when changing materials.

When changing the thickness, the die must be replaced, but by optimally designing the flow channel according to the viscosity of the rubber, it is possible to obtain accuracy comparable to that of a roller head. However, if there are several materials, it may not be possible to optimize for all rubbers. (Measuring and judging with a capillary rheometer.)

Circular Head Method

It is a method to open the sheet from the tube by making a cut in the product discharged from the cylindrical tube.

As a take-up method, there are a type that performs tubing in the horizontal direction and a type that performs tubing in the vertical direction.

The vertical tubing type does not generate weld lines, but compared to the horizontal tubing method, there is a tendency for the extrusion temperature to rise due to the higher pressure.

Although it is not suitable for many kinds of products, it is cheaper than other methods.

Since it is a cut-and-open method, Please be careful when high viscosity material sheets or thick sheets extrude, it warps.

In addition, if the viscosity is low and the thickness is thin, the sheet will stretch, so the thickness is extruded in anticipation of this.

We Mitsuba have permanent test line with Roller Head Method, so whenever we can test on request.