Sheathed Cable Line

In addition to resin cabless, we also have facilities for sheath cables for rubber wires such as silicone rubber and synthetic rubber.

Product Features

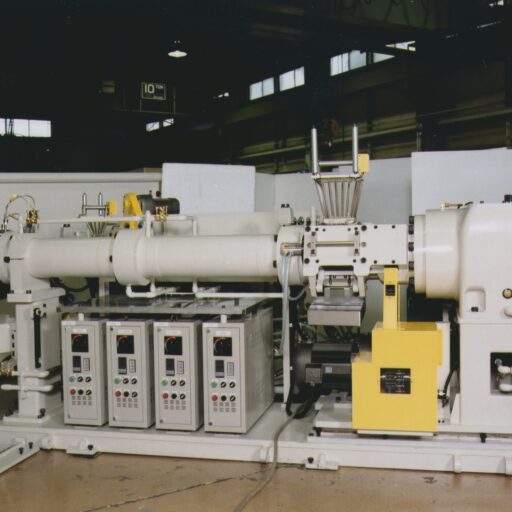

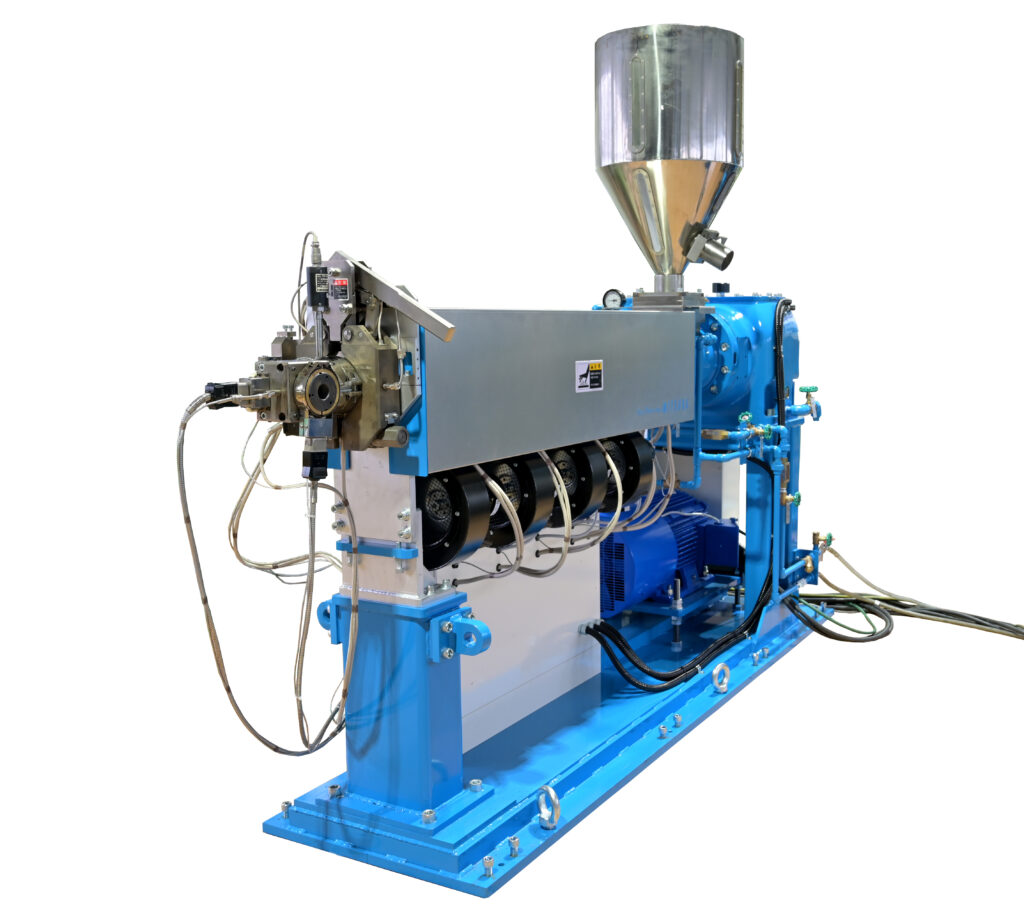

1. Plastic Extruder

We have a variety of screw sizes ranging from 25mm to 150mm class, so depending on the target wire diameter, production volume,

and we can choose the optimal size according to your installation space.

In addition to the standard type, we have newly developed a high output extruder that enables 1.5 to 2 times the output volume. By increasing the extrusion rate by 1.5 to 2 times with the same screw size as the standard type, the size of the extruder can be reduced by 1 to 2 ranks, giving you more time to consider the layout and reducing material loss.

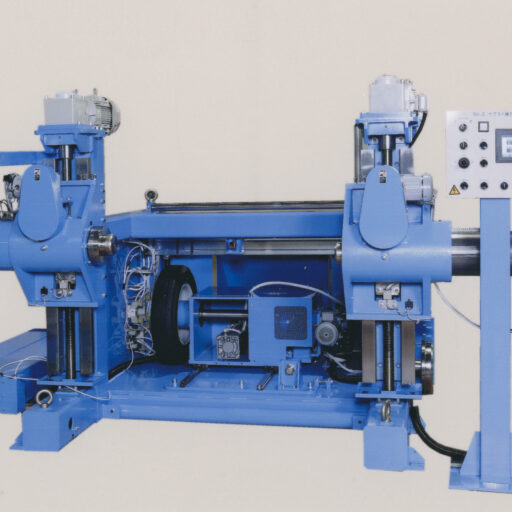

2. Rubber extruder

Rubber extruders are also available in various sizes, with screw sizes ranging from 30mm to 200mm, just like for resins.

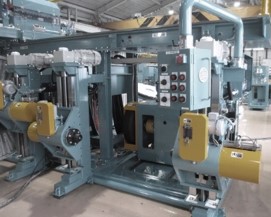

3. Pick up machine

Depending on the cable diameter, traction force, take-up speed, and layout, we will propose the most suitable model from a wide variety of models, including caterpillar type and belt-trap capstan type.

4. Supply stand/winder

We have a wide variety of supply stands and winding machines available depending on layout and drum size.

We recommend a tire-driven winder that uses commercially available tires, and is a product that has many repeat customers because it is easy to maintain and operate.

5. Accumulator

We also have thick high tension types with a pulley groove diameter of φ1500mm and a tension of up to 400kgf. We offer pulley surface treatments tailored to your application.

(Pulley groove bottom diameter φ1000)

(Pulley groove bottom diameter φ300)

6. Control panel

Since both the hardware and software are designed in-house, we work together with mechanical design to build detailed system programs, including interlocks and interlocking controls, to meet customer requests as much as possible.

Our control system, which incorporates our unique systems such as remote management, length control, and tension control, reduces operator burden, reduces loss, and improves work efficiency, and has been highly evaluated.

[Length control]

Based on the product information (conductor length, product length, color, etc.) registered in advance on the recipe screen, a command signal is output to the color feeder and color change valve, and the line speed is automatically reduced to the setup speed. After the operator confirms that the color change is complete, the machine will automatically start up to production speed with a single switch.

[Tension control]

Fine adjustments are made to the line tension registered on the recipe screen based on the actual tension data of the load cell built into the accumulator and pulling machine. This leads to improved cable quality.