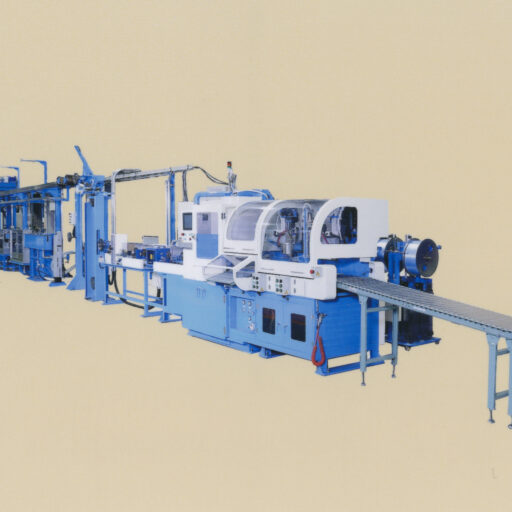

Supercritical Carbon Dioxide form Extruder

Next-generation foaming technology that has excellent solubility in resin and enables fine foaming

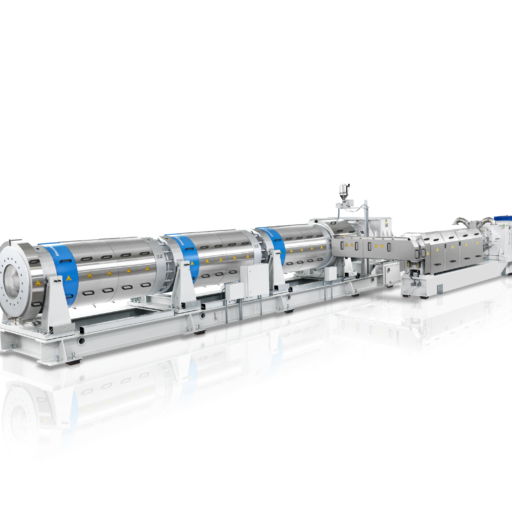

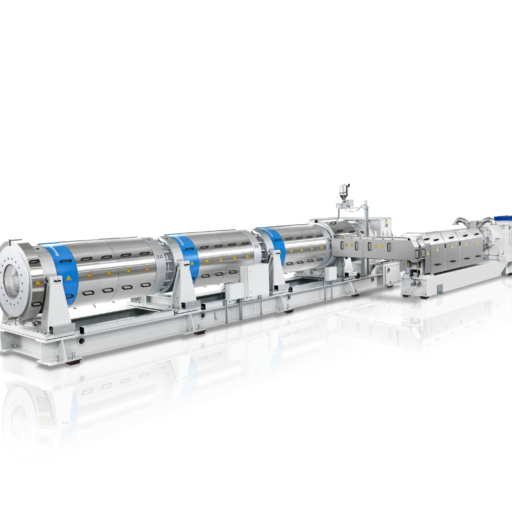

In recent years, the dramatic development of IT and IoT has required the development of communication cables that can send large amounts of information with low noise in industries such as automobiles and home appliances. This technology was developed for the purpose of realizing thinning of foamed cables by using carbon dioxide in a supercritical state and miniaturizing bubbles in order to solve these requirements.

※This development is based on the R & D project adopted in 2015, which is a strategic basic technology advancement support project (commonly known as SAPOIN).

In recent years, the dramatic development of IT and IoT has required the development of communication cables that can send large amounts of information with low noise in industries such as automobiles and home appliances. This technology was developed for the purpose of realizing thinning of foamed cables by using carbon dioxide in a supercritical state and miniaturizing bubbles in order to solve these requirements.

※This development is based on the R & D project adopted in 2015, which is a strategic basic technology advancement support project (commonly known as SAPOIN).

Product Features

- There are two gas injection methods, one that uses a melting unit and the other that injects directly from the cylinder. We can propose depending on the application, resin, extrusion shape, etc.

- Solubility in resin is about 5 times more than that of nitrogen gas.

Polypropylene resin Meltability at 200 ° C/15MPa 10% (N2 gas: 2%)

- Since the bubble diameter is 10 to 50 μm that ultra-fine foaming is possible, the coating surface is smooth and the cable has excellent flexibility.

※Bubble diameter during chemical foaming: around 200-500 μm, Bubble diameter during N2 gas foaming: around 50 μm

- The gas injection pressure is 20MPa (MAX.30MPa), which is lower than that of nitrogen gas, so you can use it with confidence.

※N2 gas injection pressure: 50 MPa (MAX.70 MPa).