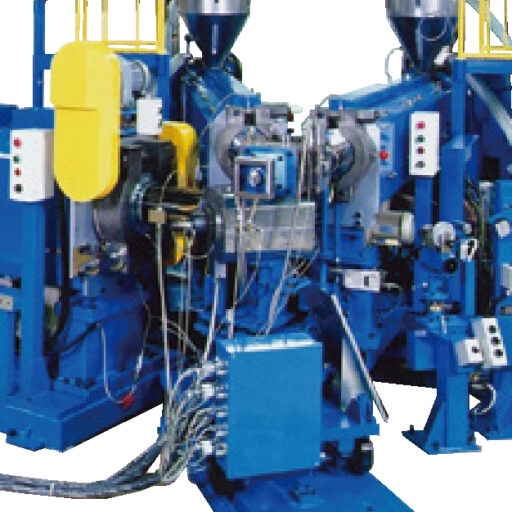

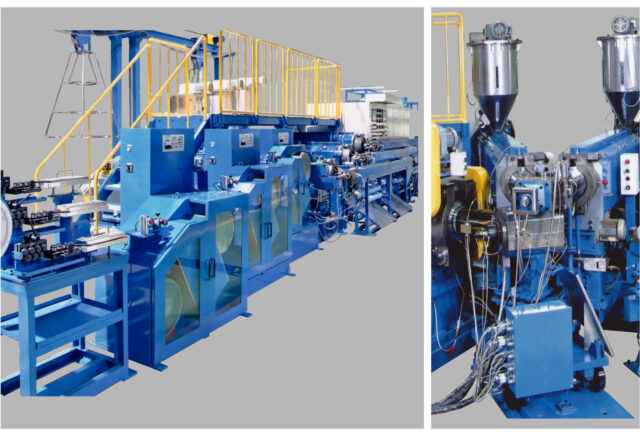

Indoor Wiring (VVF Cable) Manufacturing Line

We also support tandem lines where the insulation process and sheathing process are placed on the same line.

Product Features

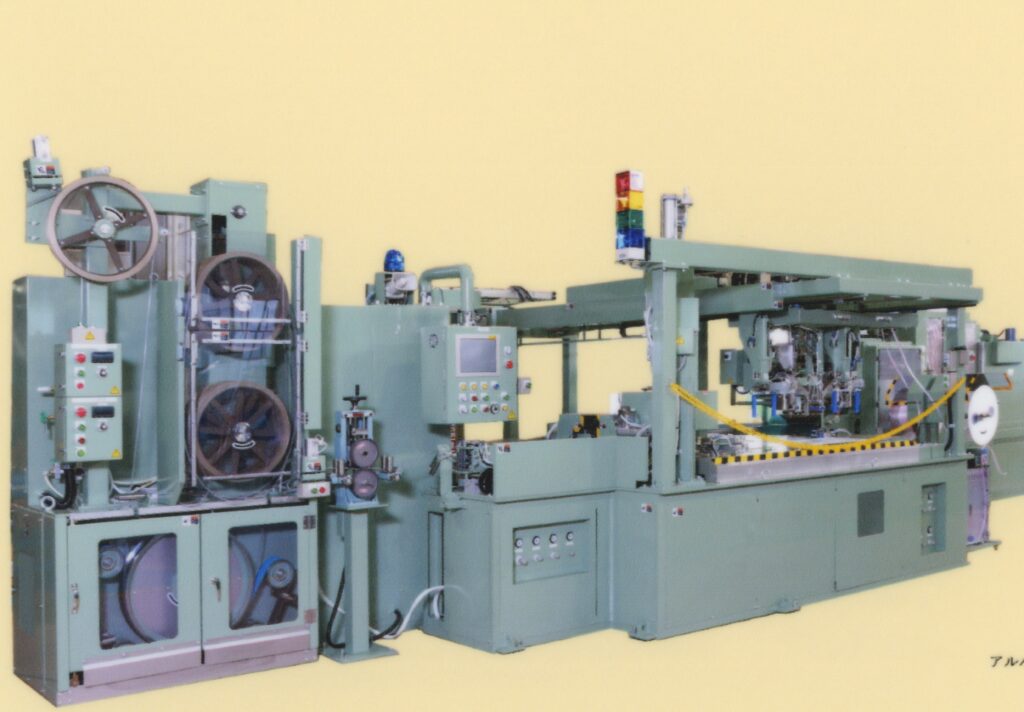

1.Increased line speed

The biggest feature of our VVF line is that we can produce at a line speed 30% faster than conventional line speeds by adopting an automatic bundling device that uses our proprietary PP band binding device.

By using two miniaturized PP band binding heads, it is now possible to bind in two locations at the same time, significantly shortening the binding takt time. (Reference: Line speed 250 to 260 m/min when bundle length is 100 m and 2 places are tied)

We also accept inquiries regarding delivery to shrink equipment (outsourced products).

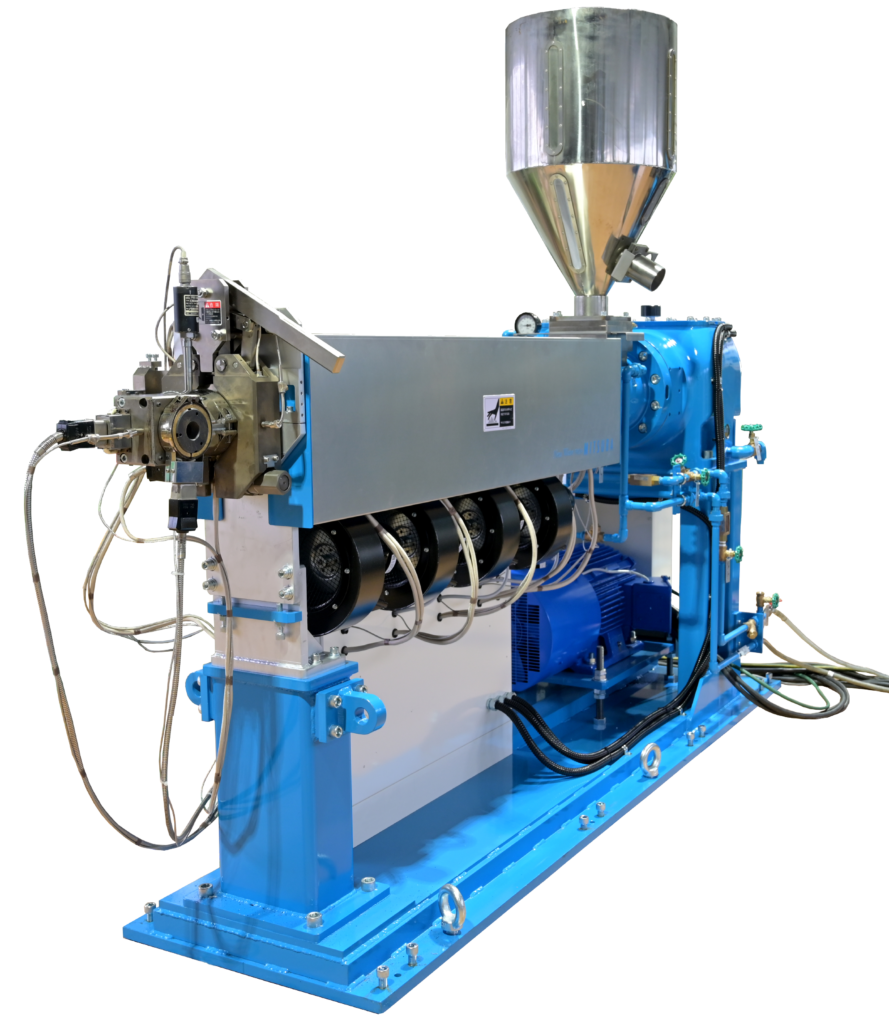

2.Extruder

As the line speed increases, the extrusion volume also becomes necessary. We have standard machines with screw diameters up to φ150mm class.

In addition, when considering updating an existing line, it is expected that there will be restrictions on the installation space for the extruder, but by using a high-output type extruder, the size of the extruder can be the same as or smaller than the existing extruder. We can also make suggestions.

3. Provided system

In addition to extruders and automatic bundling machines, we design and manufacture line equipment and control panels such as supply stands, take-off machines, accumulators, water tanks, etc. in-house.As a tandem line from the insulation process to the sheathing process, We will provide the system.

4.Control panel

Since both the hardware and software are designed in-house, we work together with mechanical design to build detailed system programs, including interlocks and interlocking controls, to meet customer requests as much as possible.

Our control system, which incorporates our unique systems such as remote management, length control, and tension control, reduces operator burden, reduces loss, and improves work efficiency, and has been highly evaluated.

[Length Control]

Based on product information (conductor length, product length, color, etc.) pre-registered in the recipe screen, it outputs command signals to the color feeder and color change valve while automatically decelerating the line speed to setup speed. After the operator confirms the color change is complete, production speed is automatically resumed with the push of a single switch.

[Tension Control]

Fine adjustments are made based on actual tension data from load cells integrated into accumulators and take-up units, compared to the line tension registered in the recipe screen. This contributes to improved cable quality.