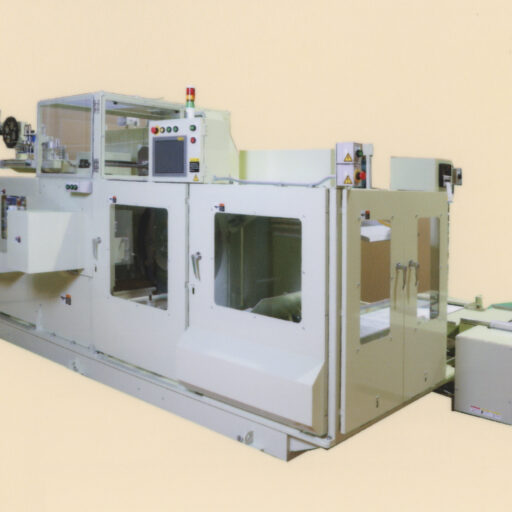

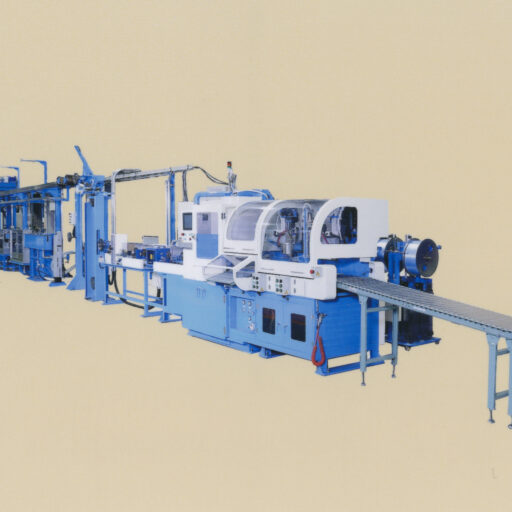

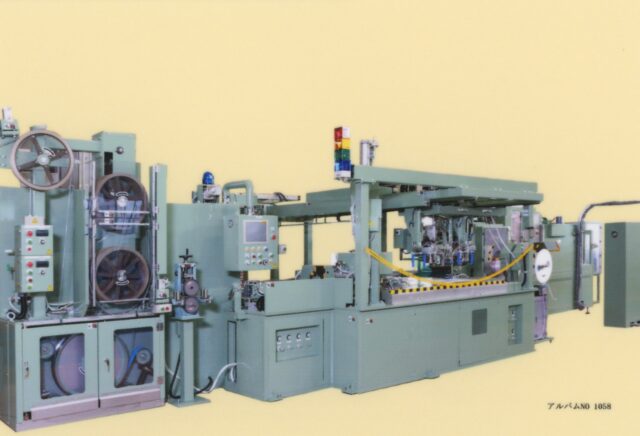

Automatic Tying Machine with Self-Developed Small PP Band Tying Device.

In addition, it has not only the appearance but also a full range of functions. It can be used for automotive cable production with line speed of 1200 m/min and production speed of VVF cable with short bundle length can be increased, because it uses 2 tying devices the switching tact can be shortened.

*Depending on cable application and property, there are models for cord and laminate tape.

Product Features

1.Maintainability

Since the tying device is small and can be removed from the tying machine body, maintenance work can be performed in a large space, which reduces the stress on the operator.

If you have spare tying devices, you can replace and send back only removed one to our company for breakdowns and overhauls that you cannot deal with, so it will not hinder daily production.

2.Production Speed-up

In the case of a tying with a short bundle length such as a VVF cable, up to now it was not possible to increase the production speed due to the limitation of the tying tact. Since two compact tying devices can be installed, tying at two locations at the same time will improve the production speed. (Based on our actual results, the bundle length is 100 m, the line speed is 260 m/min when bundling at two locations)

3.Traverse Section

By adopting an electronic traverse, you can freely set the temporary stop of the turn position, the winding start position, the descending/ascending pitch, etc. on the touch panel, so you can wind under the optimal conditions according to the characteristics of the cable.

Also, by managing the recipes that have been set, you can shorten the setup time and reproduce the bundle appearance regardless of the skill of the operator.

4.Efficiency during setup

Since the height of the bundle frame is a screw shaft type, it can be changed without using any attachments or tools.

5.Adjustment of Tying Position

Since it can be tied according to the position of the winding start end and the termination, it is possible to prevent problems such as long protruding cables damaging the shrink wrap in the next process, or the cables getting caught during transport and stopping the line. You can also adjust the extra length of the PP band. By making the extra length longer, it becomes easier to manually remove the PP band without using tools such as scissors and will improve the next process work.