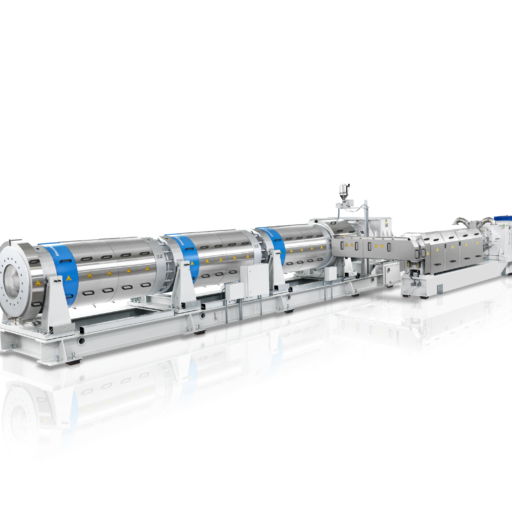

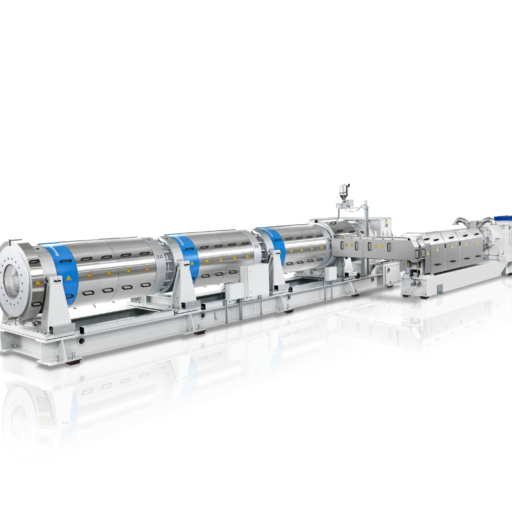

XPS board (Insulation material) Production

KraussMaffei is a market leader in extrusion systems for physical foaming.

Throughput is high as 2,000 kg/h and various plastic processing is possible from thin to thick.

Environmentally friendly foaming agents such as CO2 and ethanol contributes to society.

It is Perfectly harmonious and no-waste system components reusing of start-up materials

Throughput is high as 2,000 kg/h and various plastic processing is possible from thin to thick.

Environmentally friendly foaming agents such as CO2 and ethanol contributes to society.

It is Perfectly harmonious and no-waste system components reusing of start-up materials

Product Features

- Having high throughput of 2,000 kg per hour with a wide extrusion die, the combination of ZE(Twin-screw extruder) & KE(Single screw extruder) makes XPS foam board(a hard flame-retardant heat- insulating styrofoam often used for building materials) be produced smoothly.

- It can produce the width of 600 mm or 1200 mm. The plate pressure can be changed freely within the range of 30 to 160 mm. Ancillary downstream equipment cools the board, cuts and rolls it to the desired dimensions

- The KME foam extruder, which consists of a ZE type co-rotating twin-screw extruder and a KE type single-screw extruder, is suitable for high throughput processing of all foaming agents (especially environmentally friendly types) used all over the world.

- The high-precision of cartridge heater attached to each boundary of the hydraulic heating/cooling system consisting of four temperature control divisions makes it possible to quickly make an effect in the heating/cooling of the wide extrusion die made by Krauss Maffei Extrusion. This feature is of crucial importance in improving product quality and at the same time ensures a reduction in start-up time.

- It is possible to add more heat insulating housing to prevent heat leakage to the outside, which leading to energy saving.