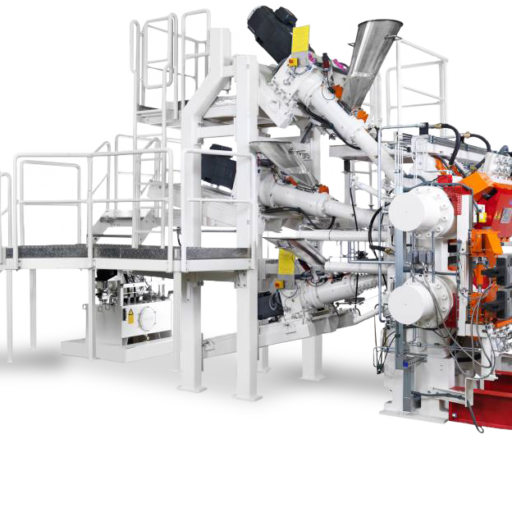

Cost-effective production of strips and profiles

★State-of-the-art control, regulation and monitoring system for extrusion technology

Advantage

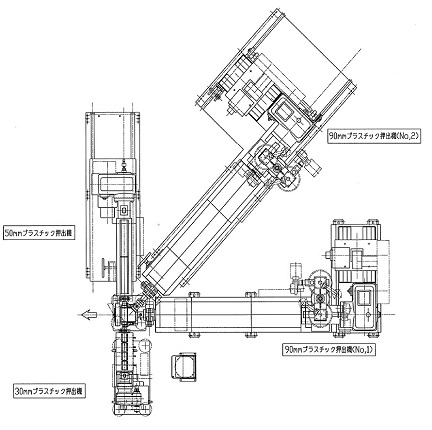

・For "In-line to extrusion system for tire parts"

・Supports a wide variety of cross-section strips and high-precision production of profiles

Specification

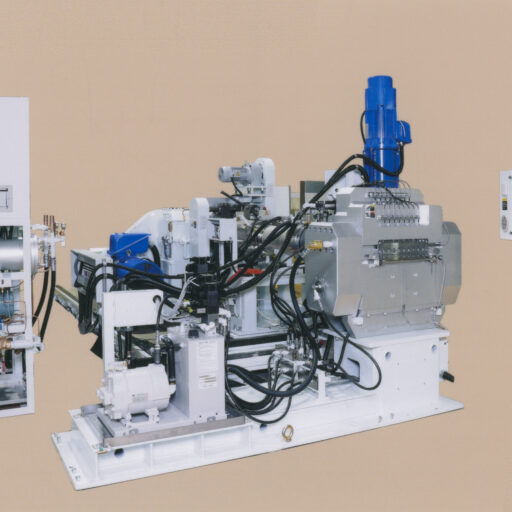

・Energy efficiency, water-cooled three-phase current asynchronous motor

・Features and introduction of cylinder and screw products using high quality materials with high wear resistance

Advantage

・For "In-line to extrusion system for tire parts"

・Supports a wide variety of cross-section strips and high-precision production of profiles

Specification

・Energy efficiency, water-cooled three-phase current asynchronous motor

・Features and introduction of cylinder and screw products using high quality materials with high wear resistance

Product Features

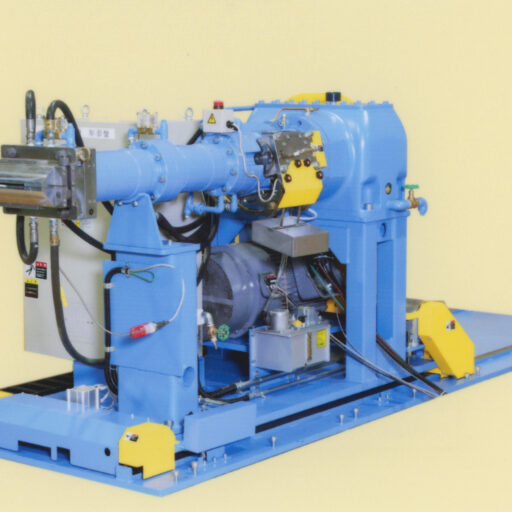

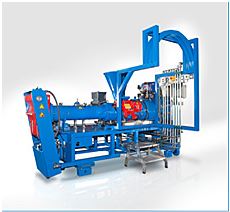

Mini roller head system

= High quality and production reliability =

- Mini roller head system is highly evaluated by the market for quality improvement and productivity and durability improvement.

- The mini roller head system is used for only the extruder, injection head, and 2-roll calendar developed exclusively by KME.

- A wide variety of filler strips can be precisely manufactured with a thickness of 0.5 to 4 mm and a maximum width of 120 mm.

- Specially stored and hardened calendar rolls maintain a certain level of productivity and provide high reliability.

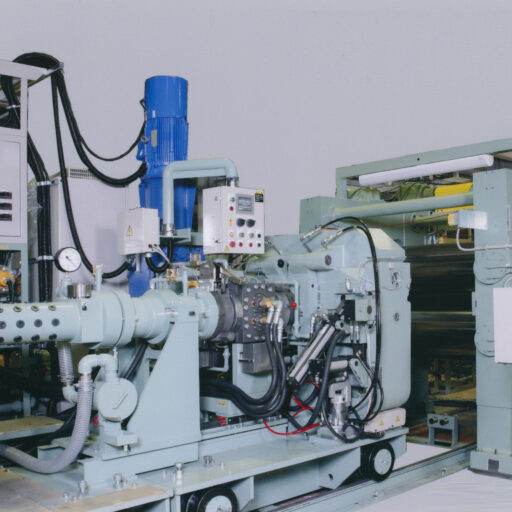

- Another important advantage is the supply option that returns the edge trimming material (constantly accumulated during manufacturing) to production and uses it, which is a nature-friendly energy-saving system that contributes to the saving of raw materials.

- In-line is possible with the tire component extrusion system, and major tire manufacturers around the world are already enjoying the product quality and high throughput rate.