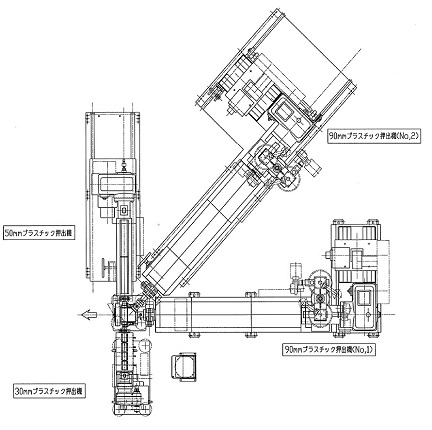

rubber profile extrusion line

We offer a variety of extruded shapes to suit your needs, so please feel free to contact us.

Product Features

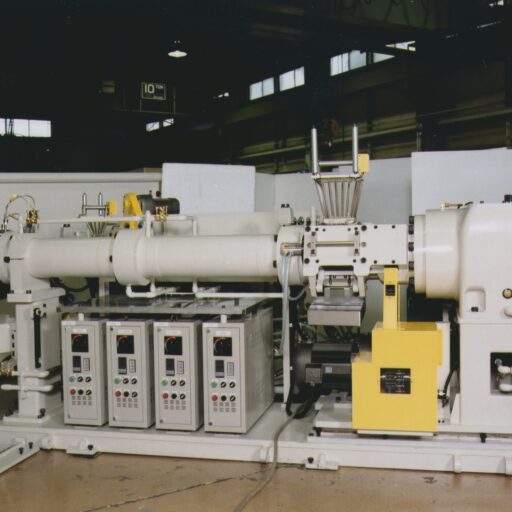

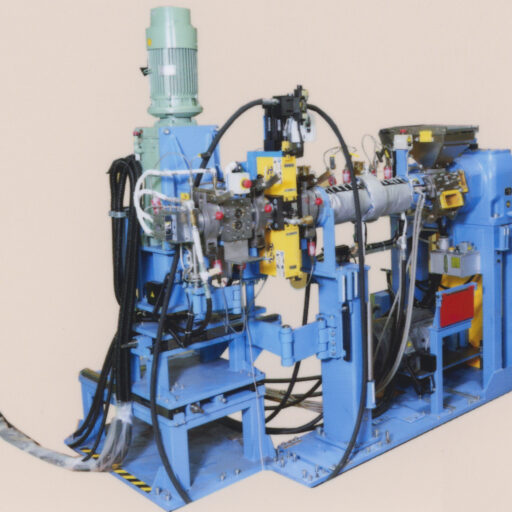

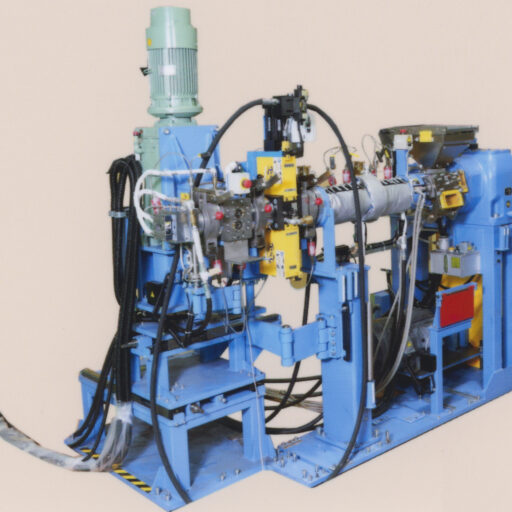

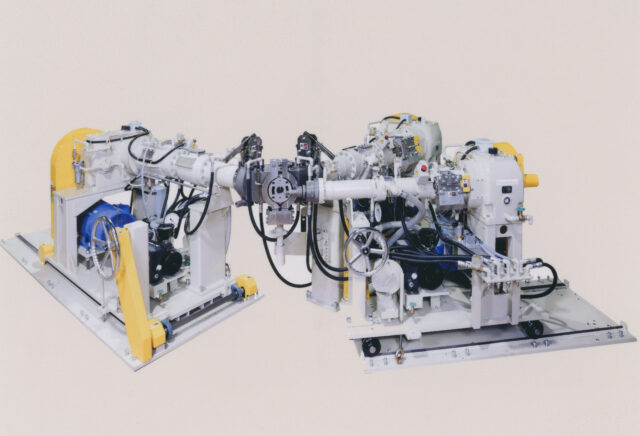

Rubber extruder

Abundant Product Composition met applications and needs you have!! The rubber extruder, which is one of our signboard products of Mitsuba Manufacturing Co., Ltd. has been adopted by many users both in Japan and overseas, with nearly 100 extruders annually since its establishment.

addition to its achievements and experience, we design screws and flow paths in-house based on material data that makes full use of measuring instruments such as Brabender viscometers and Capillary rheometers, and we also assemble in-house major parts with our own high-performance processing machines and skilled technicians.

Having small extruders like screw size φ20 mm to larger large extruders like φ200 mm, our extruders are used in various fields such as automobile hoses and tyres, building sealing parts, medical tubes, electric cables, and printing rolls and so forth. If advising us the application and specifications, we are glad to propose the most suitable equipment including front and rear equipment.

Vertical Vulcanizer Tank

- Since the work surface is vulcanized while maintaining a non-contact state until it hardens, there are no marks on the belt or guide roll.

- Since vulcanization is performed while maintaining a perfect circle upward, it is ideal for thin-walled tubes and tubes made of low-viscosity materials that are worried about tube-crushing.

- Since there are no contact objects such as belts and guide rolls, it is also ideal for vulcanization of irregularly shaped products with protrusions on the bottom surface.

- Since heat is applied at a uniform temperature over the entire circumference of the work, good quality products with no uneven vulcanization can be produced.

- No need for longitudinal installation space.

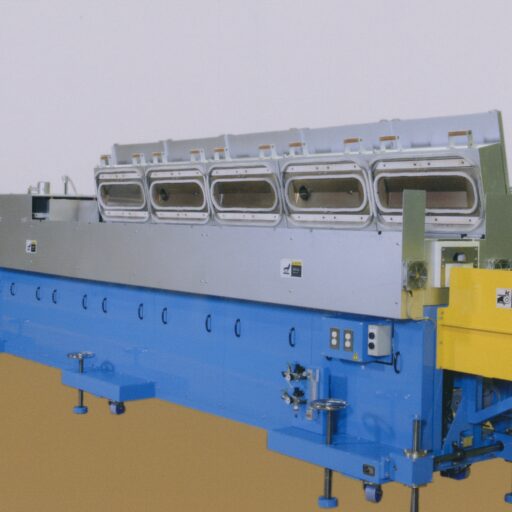

Horizontal Vulcanizer

- Compared to vertical vulcanizer tanks, production is possible at faster line speeds. (Note: Depends on vulcanization conditions and installation space)

- Since the height of the equipment is low, it can be installed at the height of a typical factory without the need for building renovation work.

- Since work can be done on the floor, maintenance and work can be done easily.

【Suitable product】

A tape-like products or few uneven surfaces profile products (especially on the bottom side)

HAV Vulcanizar

- Vulcanization is possible regardless of the vulcanization system.

- If you cannot provide a furnace length due to space restrictions, you can use a 3-stage system.

- Adopts a special heat insulating structure to improve safety.