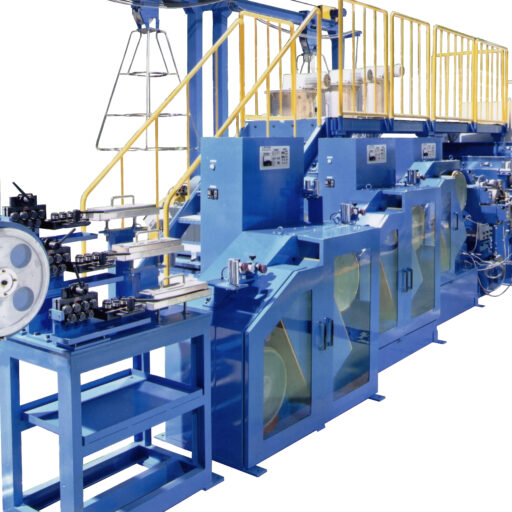

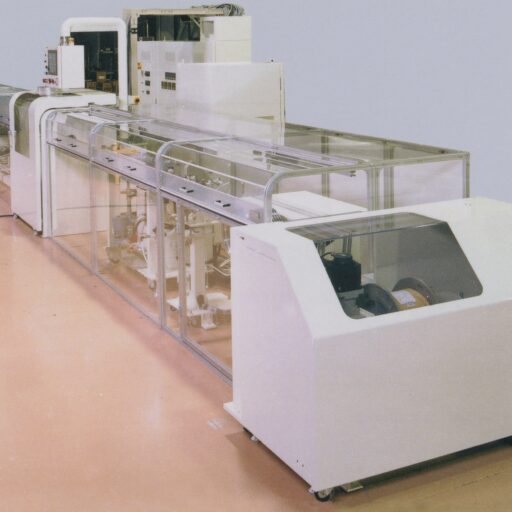

Inverter-controlled preheater

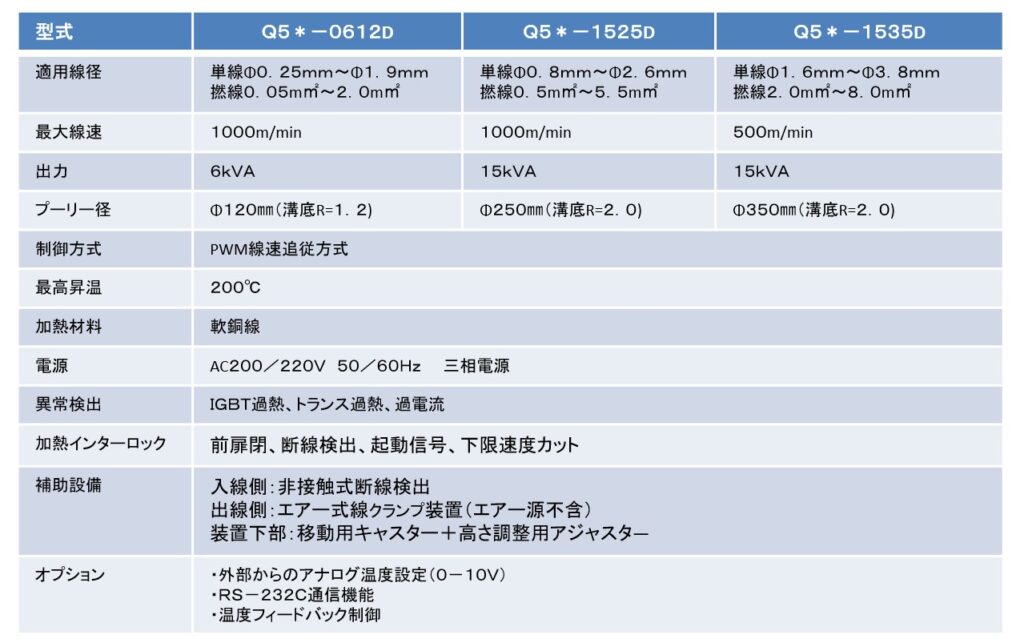

Our preheater (Q5 Series) has a proven track record of over 30 years since the first unit was developed using proprietary technology in 1993. Since its launch, we have continuously refined its performance and usability based on valuable feedback from our customers. This has resulted in repeat orders and high customer satisfaction. The Q5 Series offers three models tailored to wire sizes: single wires from φ0.25 to φ3.8 mm and stranded wires from 0.05 to 8.0 sq.

Product Features

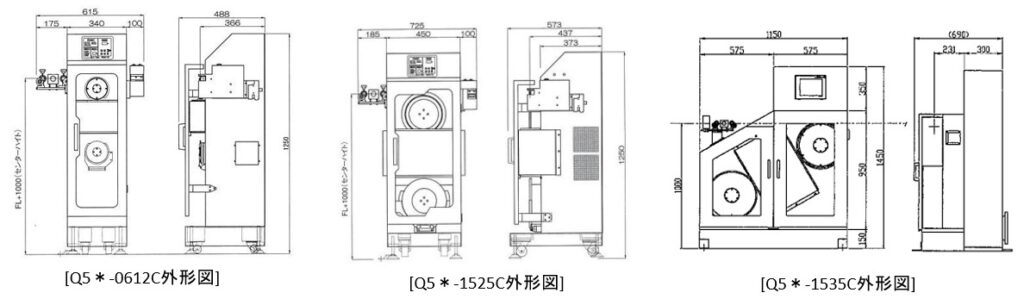

1. Abundant variation

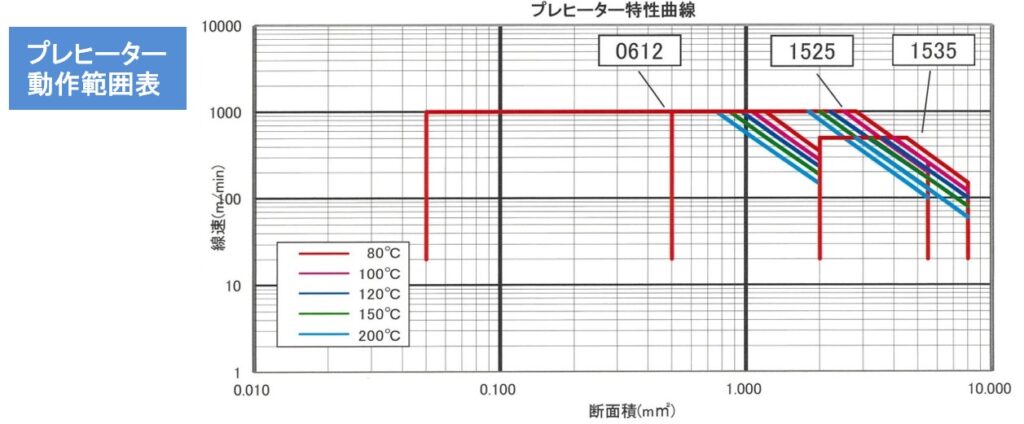

Three models are available for wire sizes: single wire φ0.25 to φ3.8 mm and stranded wire 0.05 to 8.0 sq.

2. Made in Japan

This preheater is designed and manufactured entirely in Japan by Mitsuba Manufacturing. The major purchased components used are also sourced from domestic manufacturers, ensuring reliable quality for your peace of mind. Compared to overseas-made models, we can provide faster response times for part replacements and repairs in case of failure, both in terms of delivery and service.

3. Energy saving

The power supply is a three-phase power source that is once converted to direct current internally, resulting in low reactive power and economical running costs.

4. Line speed following

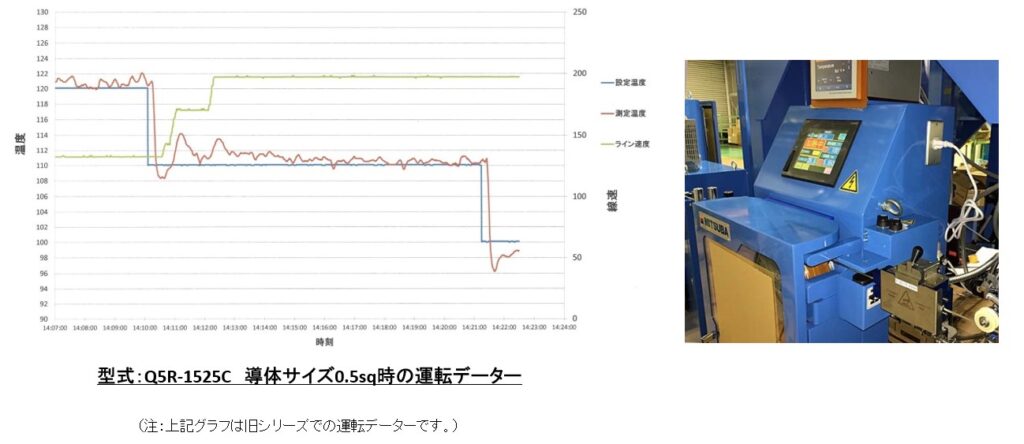

The line speed follows the line speed from 20 m/min and the heating temperature of the wire is controlled so that production quality can be maintained at the same level as the normal production speed during start-up and shutdown, thereby reducing wire loss.

5. All season

Constantly monitoring ambient temperature,

6. Ease of operability

By setting line size, line speed, and temperature conditions on the touch panel, operation can be started without making fine adjustments during production. Also, by recalling the conditions registered on the recipe screen, reproducible operation can be started in a short time, regardless of the operator’s skill level.

7. Space saving

The use of an 800HZ high-frequency transformer makes the entire device compact and can be installed in a minimum amount of space.

8. PLC control

The use of commercial PLC for temperature control shortens shutdown period when breakdown, and it makes possible to setup optional multistage control of production speed according to conditions at start-up and shutdown.

9. Temperature feedback control (option)

The standard type without feedback control can be controlled within -5% of the set value, but the program is based on the electrical resistance at 100% copper. Depending on the electrical resistance of the conductor, there may be an error in the set temperature, or the actual temperature at crosshead entry may be lower than the set value due to heat radiation depending on the wire size and wire speed.

To further improve quality, a non-contact thermometer (purchased externally) can be attached to the outgoing part of the preheater to measure the conductor temperature and correct the preheater current value to produce a conductor surface temperature close to the set value.