Silicone Rubber Wire Line

Silicone rubber electric wires, which take advantage of the features of materials such as flexibility and heat resistance, have been reviewed and used in various fields such as charging cables for electric vehicles, in-vehicle cables, and electric / electronic devices.

Our silicone rubber wire line has a rich product repertoire including extruders suitable for various requests such as customer's product specifications, layout, production volume, etc. from thin wires with an outer diameter of 1 mm or less to thick wires with an outer diameter of nearly 30 mm. We select each device from among them and propose a silicone rubber wire line that incorporates many years of Mitsuba achievements and experience.

Our silicone rubber wire line has a rich product repertoire including extruders suitable for various requests such as customer's product specifications, layout, production volume, etc. from thin wires with an outer diameter of 1 mm or less to thick wires with an outer diameter of nearly 30 mm. We select each device from among them and propose a silicone rubber wire line that incorporates many years of Mitsuba achievements and experience.

Product Features

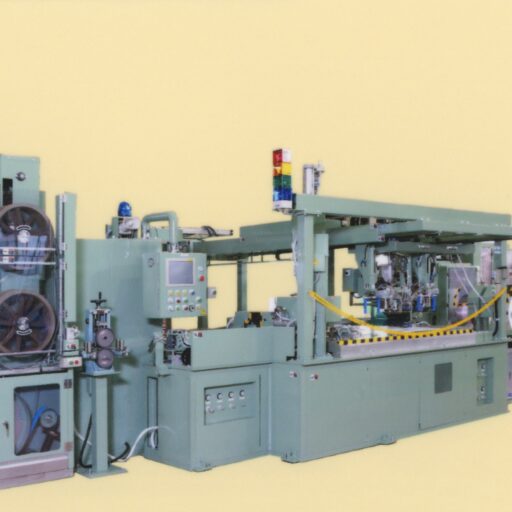

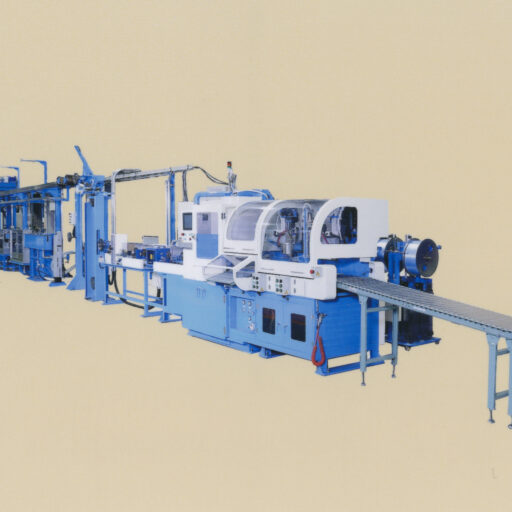

1.Supply stand

- We have various types from low-priced cantilever shaft type for lightweight small-diameter drums without lifting function to type with lifting function for large heavy-duty drums with a collar diameter of Φ1000 mm or more.

Brake type and drive type can be selected for any type.

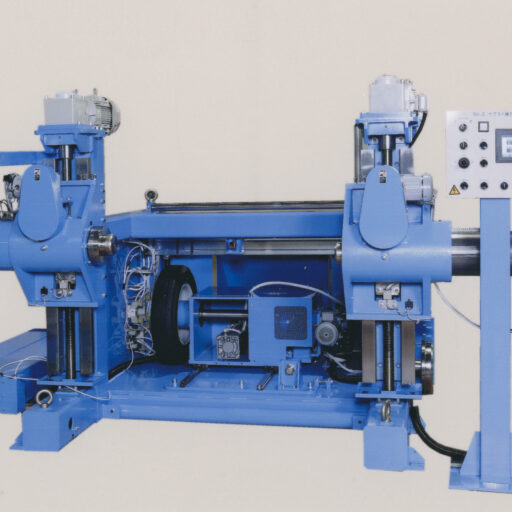

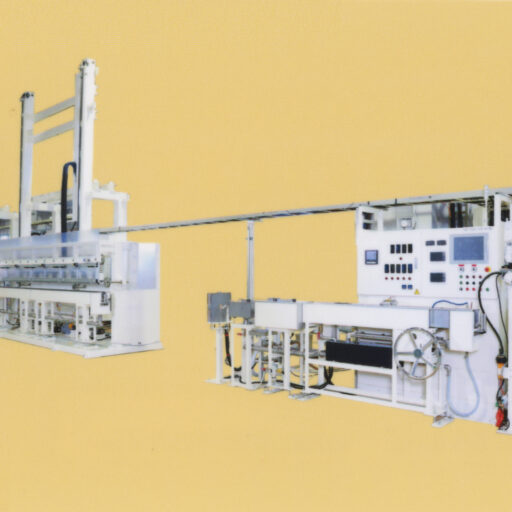

2.Silicone rubber extruder

- We have screw sizes from 20 mm to 120 mm depending application and throughput.

We also have vent type extruders with degassing function in each size, so we can propose and provide the most suitable extruder to meet your needs.

- As a measure against wear by silica, wear-resistant metal is used as standard on the inner surface of the cylinder, which is difficult to replace.

- We use a screw that suppresses heat generation by shearing, for silicone rubber shows a sensitive cross-linking reaction due to changes in extrusion temperature.

3.Preheater

- Depending on the wire diameter, you can choose from two types: induction heating type and electric furnace.

①Induction heating type preheater

The line heating speed is controlled from the line speed

②Electric Heating Furnace Type Preheater

As a preheater for sheath cables, fiber cables, and thick cables that cannot be used with the induction heating type

Since wire run straight in Furnace, thick cable can be used.

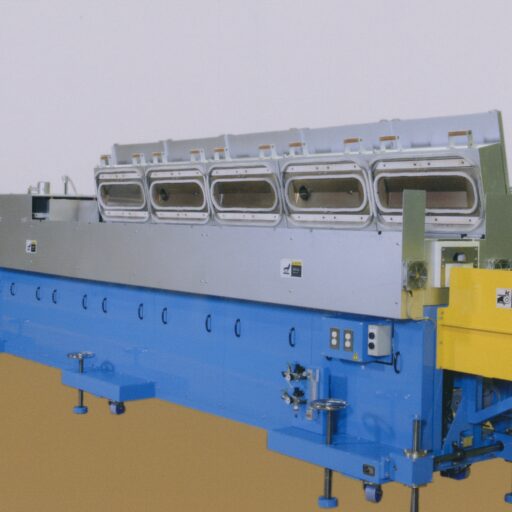

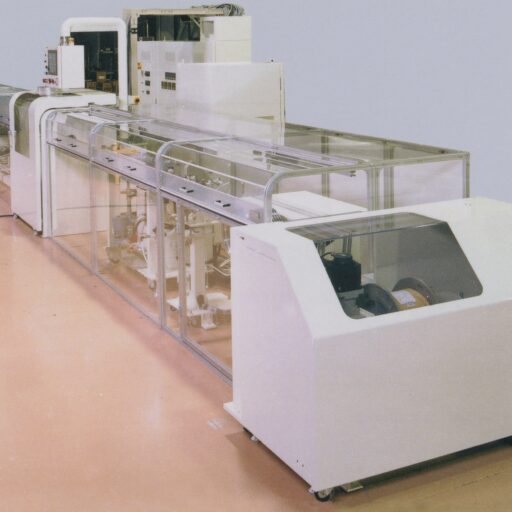

4.Horizontal Vulcanizer

- Compared to vertical vulcanizer tanks, production is possible at faster line speeds. (Note: Depends on vulcanization conditions and installation space)

- Since the height of the equipment is low, it can be installed at the height of a typical factory without the need for building renovation work.

- Since work can be done on the floor, maintenance and work can be done easily.

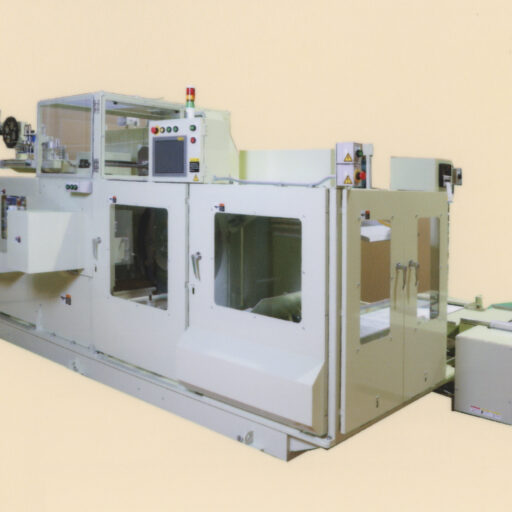

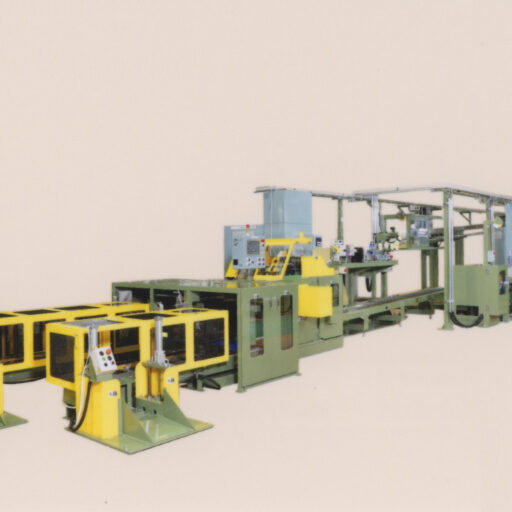

5.Coiling Machine

- Since two compact tying devices can be installed, tying at two locations at the same time will improve the production speed.

(Based on our actual results, the bundle length is 100 m, the line speed is 260 m/min when bundling at two locations)

- By adopting an electronic traverse, you can freely set the temporary stop of the turn position, the winding start position, the descending/ascending pitch, etc. on the touch panel, so you can wind under the optimal conditions according to the characteristics of the cable.

Also, by managing the recipes that have been set, you can shorten the setup time and reproduce the bundle appearance regardless of the skill of the operator.

- Since it can be tied according to the position of the winding start end and the termination, it is possible to prevent problems such as long protruding cables damaging the shrink wrap in the next process, or the cables getting caught during transport and stopping the line.

You can also adjust the extra length of the PP band. By making the extra length longer, it becomes easier to manually remove the PP band without using tools such as scissors and will improve the next process work.