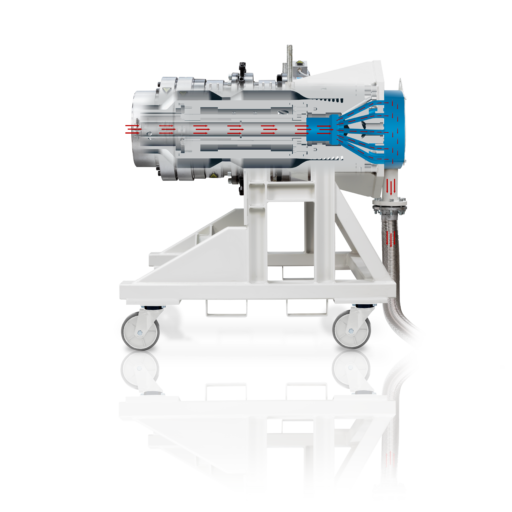

QuickSwitch System

With the QuickSwitch System, the pipe size can be changed in minutes without stopping the line with just the push of a button.

And only a minimal amount of scrap is generated while the change is taking place.

Product Features

The head is equipped with a pin that can be inserted or retracted with respect to the direction of extrusion which changes the wall thickness of the pipe.

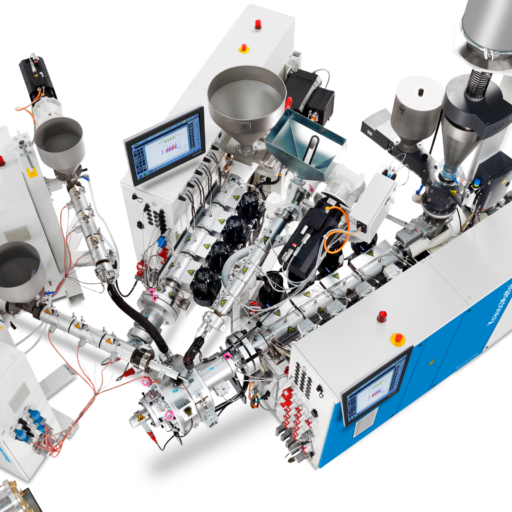

The melt pipe is expanded at the suction bell to the right dimension for calibration as it arrives at the calibrating basket, which consists of multiple segments that move to produce the set dimensions.

The haul-off machine has its upper tracks pressed by a pneumatic cylinder, while its lower tracks are maintained by means of electrical motors, and as the pipe dimensions are monitored by a sensor at the inlet, its hauling force is controlled to remain constant. Thus, the appropriate hauling force is applied even while the dimensions of the pipe are changing.

The cutter also adjusts automatically to the monitored pipe dimension.

The QuickSwitch System can be deployed either as a complete fully automated line, or in independent modules, first, to form a manually operated QuickSwitch system, and eventually moving on to a fully automatic line.

Applicable pipe sizes

PO pipe: φ25 – 63, φ70 – 160, φ160 – 250

PVC pipe: φ90 – 160