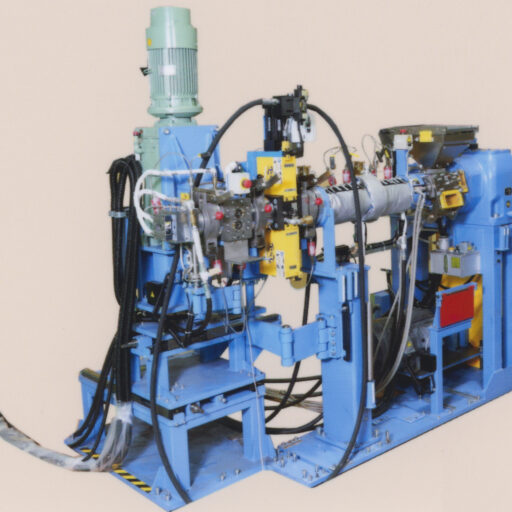

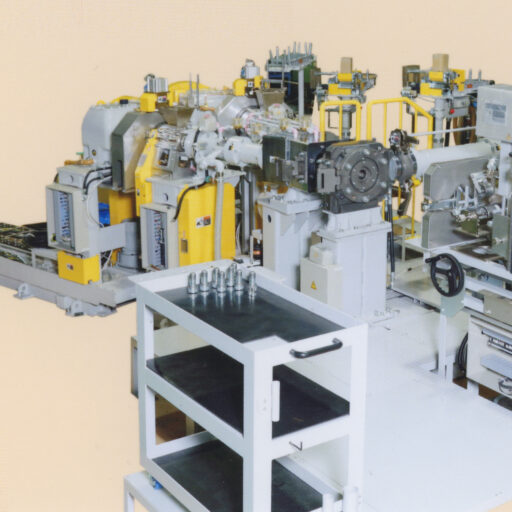

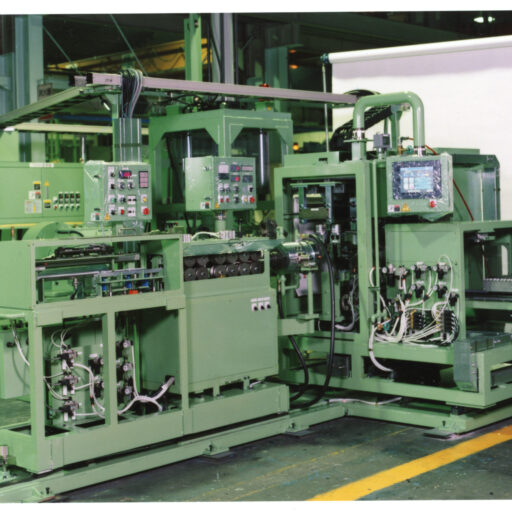

Silicone Rubber Exruder

In recent years, silicone rubber materials have been used in various fields of such as electronic parts, electric vehicles, food, and medical care other than those used in conventional industrial products, due to the evaluated properties such as odorlessness, heat resistance, cold resistance, and flexibility, low chemical reactivity.

Mitsuba's silicone rubber extruder is designed and manufactured as a dedicated machine with various ingenuity in order to maintain the quality and to cope with the properties peculiar to silicone rubber materials in these fields where demands are strict.

Product Features

Abundant Equipment Variations

We have screw sizes from 20 mm to 120 mm depending application and throughput.

We also have vent type extruders with degassing function in each size, so we can propose and provide the most suitable extruder to meet your needs.

Screw shape

We use a screw that suppresses heat generation by shearing, for silicone rubber shows a sensitive cross-linking reaction due to changes in extrusion temperature.

Wear resistance measures

As a measure against wear by silica, wear-resistant metal is used as standard on the inner surface of the cylinder, which is difficult to replace.

For screws, which are consumables, the type of flight top hardened on a general SCM material is a standard specification, but a type with wear-resistant treatment on the flight top or a type changed to a wear-resistant material is also available as an option. In this sense, you can choose any type according to the frequency of wear depending on the silica content and grain size.

Colored measures

In case of extruding translucent or white silicone rubber, if you are worried about the problem of coloring due to the metal touch on the screw and cylinder inner surface, we will propose some improvement plans based on our experience and achievements. Please contact us.

Feed section (material input section)

A separate drive type that can independently drive the rotation of the feed roll with a dedicated motor is also available as an option so that the difference in biteability depending on the material can be adjusted. Rotation control can also control the ratio to screw rotation.

In addition, for the adhesiveness and low viscosity of silicone rubber, the shape of the material input part (input from below along the feed roll so that the ribbon material does not break/cut) and the scraper material to scraped off easily are solutions. By devising the scraper (razor) material and the shape of the undercut under the feed roll, it is a dedicated machine that is different from the feed section of the general synthetic rubber.

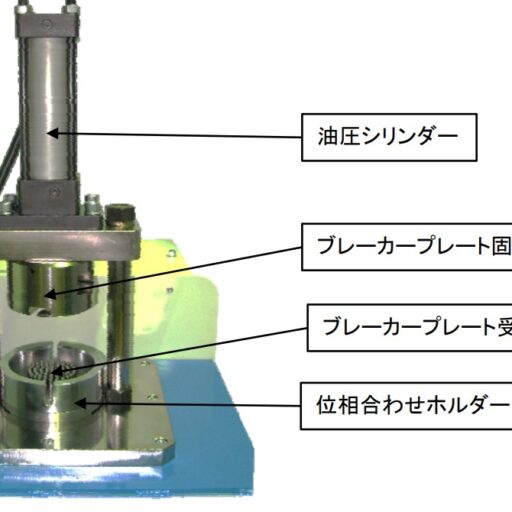

Abundant types of extrusion head

In order to meet the needs of our customers, such as crossheads for electric wire sheathing, T-dies for sheets, and multi-layer heads, we offer completely custom-made heads designed and manufactured in-house according to the extrusion shape and application.

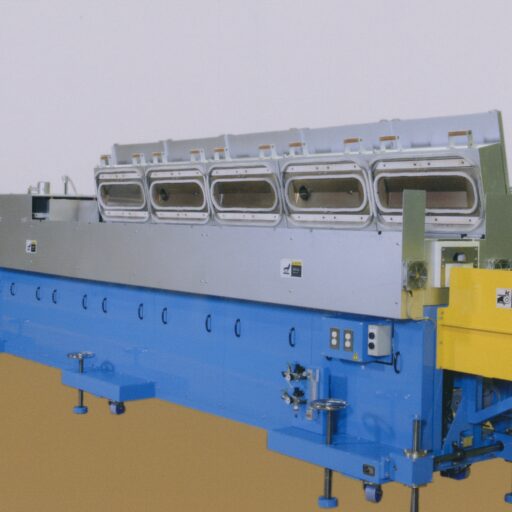

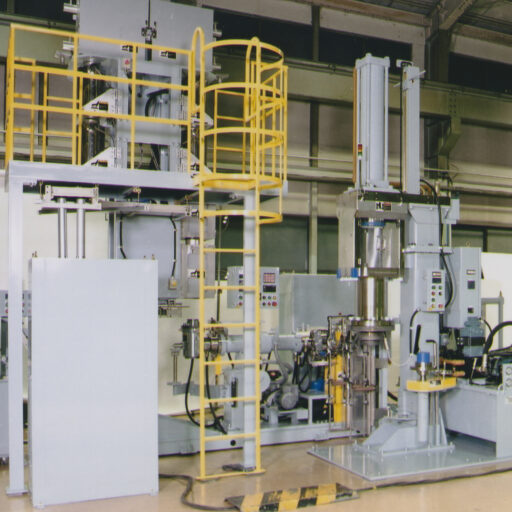

Abundant downstream devices

We also have a large number of downstream devices suitable for quality improvement and workability improvement at the manufacturing site of silicone rubber products. please refer to the links below