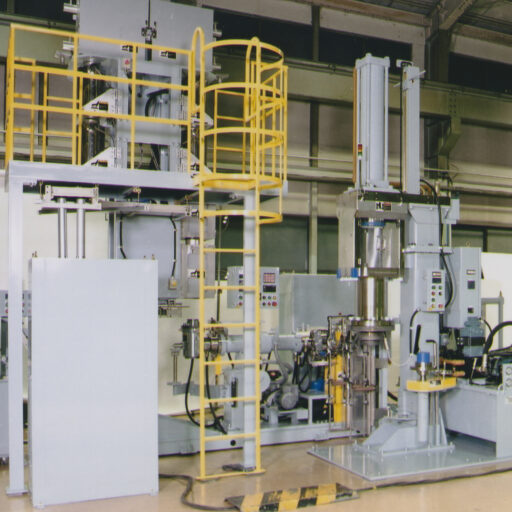

Vertical Vulcanizer Tank

Unvulcanized rubber products have just been discharged from an extruder will remain deformed when force is applied and will not return to their shape, and will easily tear if pulled.

Therefore, heat is applied to this unvulcanized rubber to cause it to react with the vulcanizing agent and sulfur, increasing the elasticity and strength of the rubber. Through this vulcanization process, rubber tubes and irregularly shaped products are manufactured from the above materials.

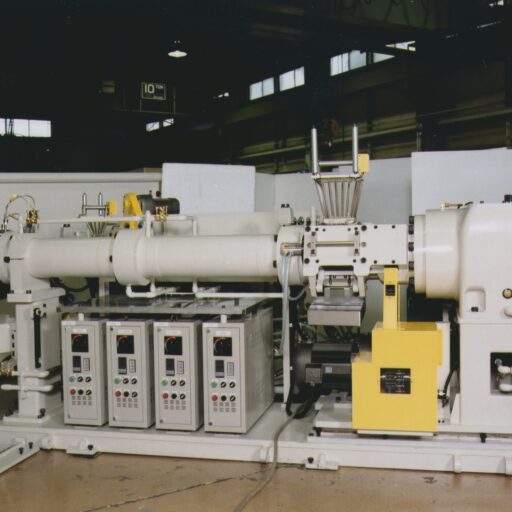

We offer two types of manufacturing equipment, a horizontal vulcanization tank and a vertical vulcanization tank, depending on the size and shape of the product.

Therefore, heat is applied to this unvulcanized rubber to cause it to react with the vulcanizing agent and sulfur, increasing the elasticity and strength of the rubber. Through this vulcanization process, rubber tubes and irregularly shaped products are manufactured from the above materials.

We offer two types of manufacturing equipment, a horizontal vulcanization tank and a vertical vulcanization tank, depending on the size and shape of the product.

Product Features

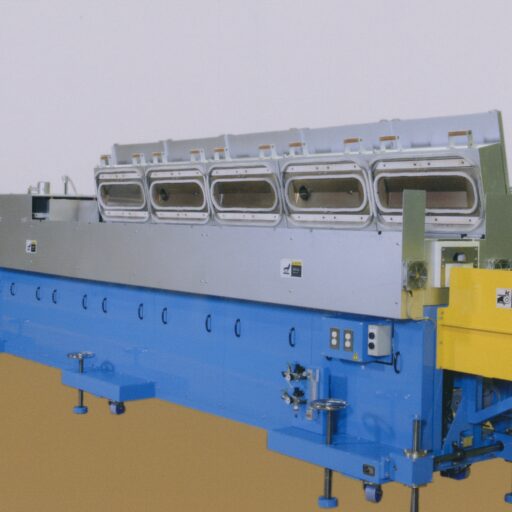

- Since the work surface is vulcanized while maintaining a non-contact state until it hardens, there are no marks on the belt or guide roll.

- Since vulcanization is performed while maintaining a perfect circle upward, it is ideal for thin-walled tubes and tubes made of low-viscosity materials that are worried about tube-crushing.

- Since there are no contact objects such as belts and guide rolls, it is also ideal for vulcanization of irregularly shaped products with protrusions on the bottom surface.

- Since heat is applied at a uniform temperature over the entire circumference of the work, good quality products with no uneven vulcanization can be produced.

- No need for longitudinal installation space.

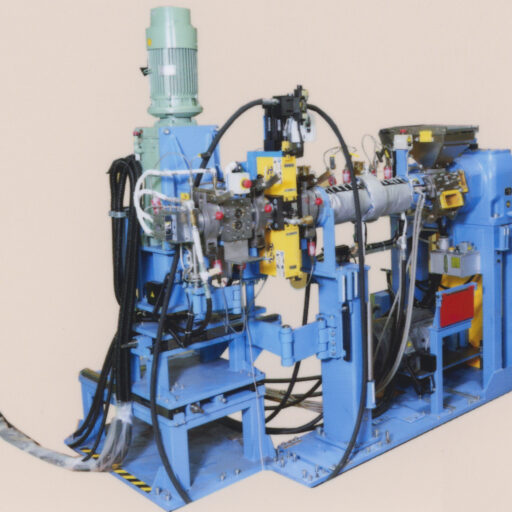

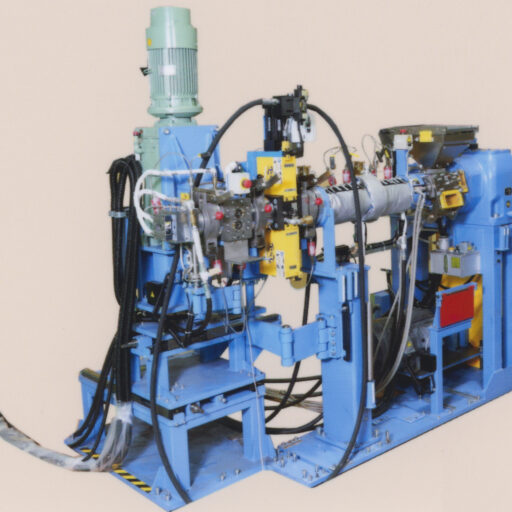

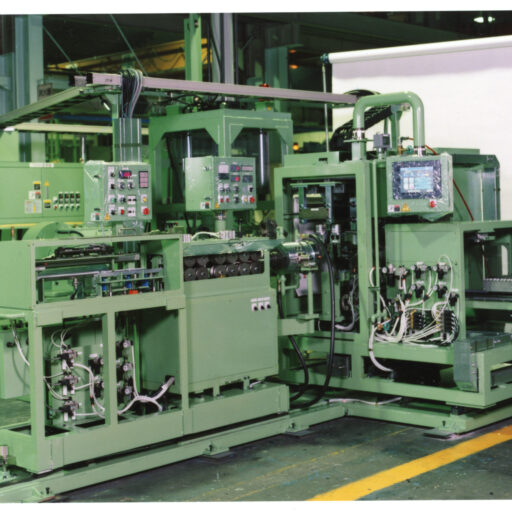

Cluster Roller Part (Patented)

- ・Uses a driven guide roller to prevent the work from slipping.

- Use a grooved guide roller so that the work is in the center of the guide roller.

- Use a grooved guide roller so that the work is in the center of the guide roller. ・The guide rollers at the inlet and outlet can be adjusted so that they are in the center of the furnace even if the size of the work changes.