Braided Horse Line

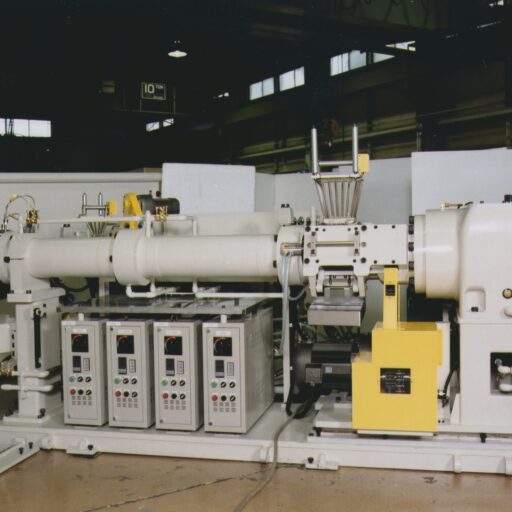

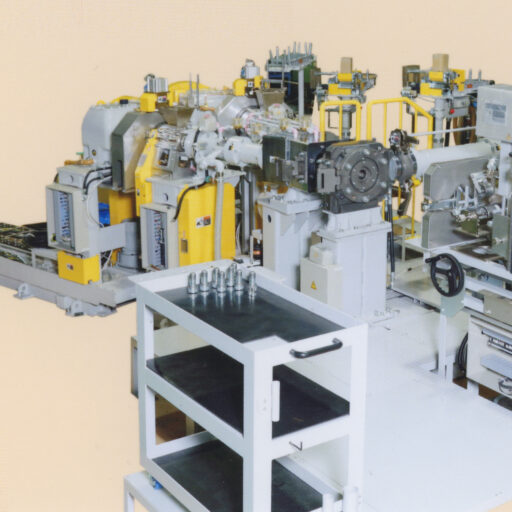

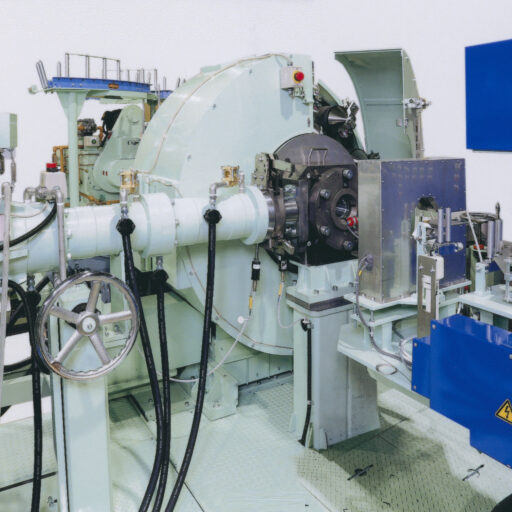

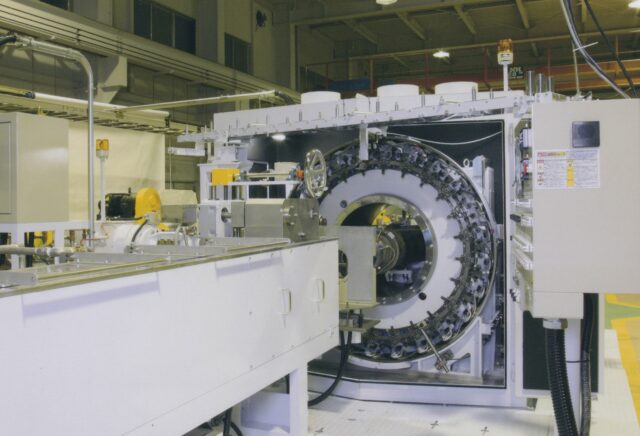

This equipment enables the integration of tube extrusion + braiding + cover extrusion without the use of a mandrel by incorporating the braider into the production line.

Because the cover extrusion takes place immediately after braiding, the yarn remains in a tidy formation.

If the available space is too confined for the full cooling length to be installed, a turning type cooling conveyor can be used.

Because the cover extrusion takes place immediately after braiding, the yarn remains in a tidy formation.

If the available space is too confined for the full cooling length to be installed, a turning type cooling conveyor can be used.

Product Features

1. extruders

- The extruder can be moved back & forth for positional adjustments, cleaning, and maintenance

(the front side comes with a fine-tuning mechanism to adjust its position relative to the braider and cover extruder) - The barrel is installed inside the braider and is supported from a single side.? It is designed to be free of any influences from pressure and weight.

- Because the hot water circulation system is mounted on a moving frame, the piping between the devices are converged into a compact formation.

1-1.tube extruder

- The tube extrusion head comes with an air injection port and lubricant injection port.

1-2.cover extruder

- Positioning pins are installed to the head adapter part (1 each, at its top & bottom) to prevent misalignment.

2.Conveyor type water cool tunnel

- The pressing conveyor enables even small diameter hoses to be hauled at a constant speed without any fluctuation.

- The insulated design of the water trough prevents dewing and condensation.

- A mist type spray nozzle is adopted.? A cooling water circulation device is installed in conjunction to enhance its cooling effect.

- Space for changeovers is made available by means of travelling in the line direction or perpendicular to the line.

- Mechanical specifications optimized to the production speed, product dimensions, installation space, and other conditions can be proposed.

3.Cutting machine with caterpillar

- Accuracy of cutting length has improved due to cutting controls.

- Production parameters can be entered from a touch-screen.

- The drive power for the cutting actuation can be provided by a range of sources from the conventional three-phase motor + clutch/brake drive to an AC servo motor.

- Mechanical specifications optimized to the production speed, product dimensions, and other conditions can be proposed.