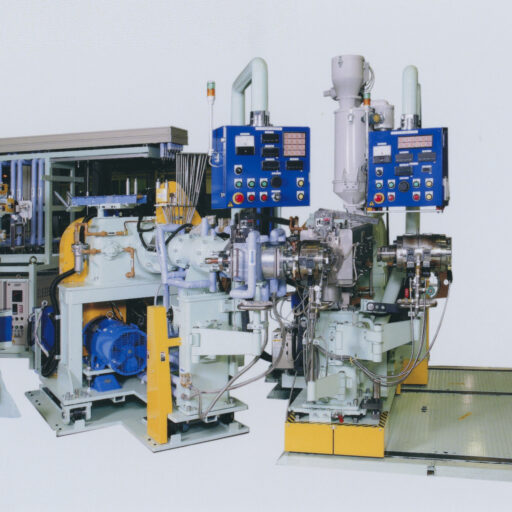

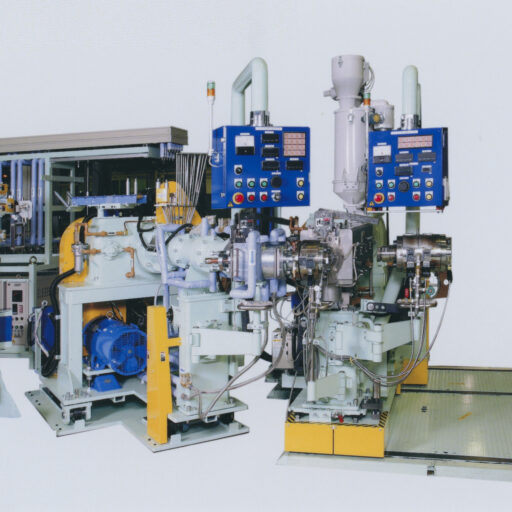

Rubber Hose Production Line

Using TPX resin as a mandrel instead of plumbum, environmentally refarding systems can be achieved.

Product Features

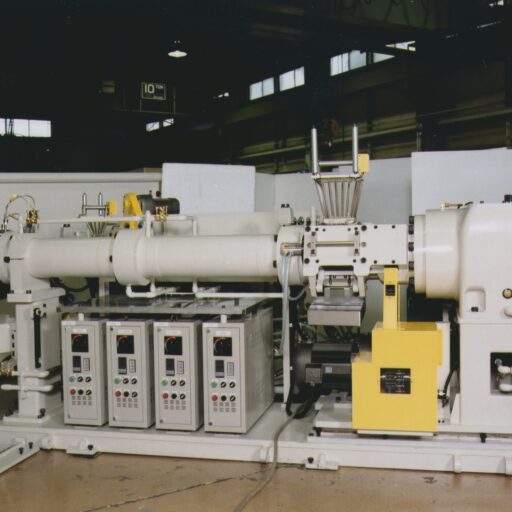

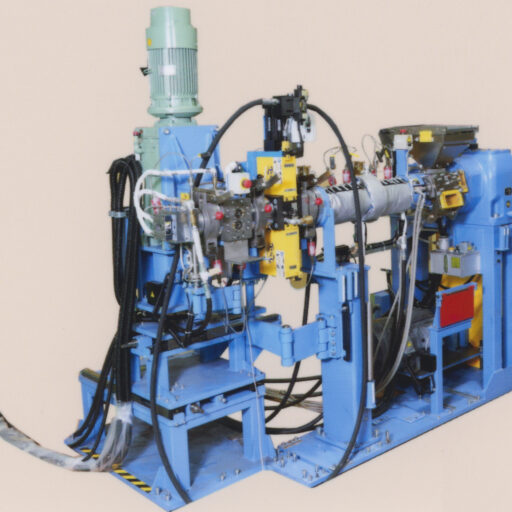

Rubber extruder

Abundant Product Composition met applications and needs you have!! The rubber extruder, which is one of our signboard products of Mitsuba Manufacturing Co., Ltd. has been adopted by many users both in Japan and overseas, with nearly 100 extruders annually since its establishment.

addition to its achievements and experience, we design screws and flow paths in-house based on material data that makes full use of measuring instruments such as Brabender viscometers and Capillary rheometers, and we also assemble in-house major parts with our own high-performance processing machines and skilled technicians.

Having small extruders like screw size φ20 mm to larger large extruders like φ200 mm, our extruders are used in various fields such as automobile hoses and tyres, building sealing parts, medical tubes, electric cables, and printing rolls and so forth. If advising us the application and specifications, we are glad to propose the most suitable equipment including front and rear equipment.

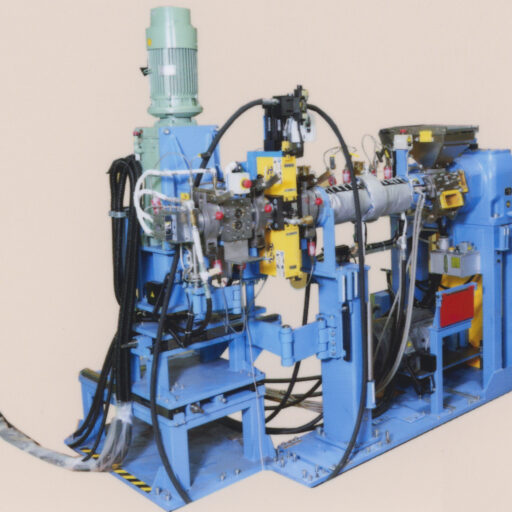

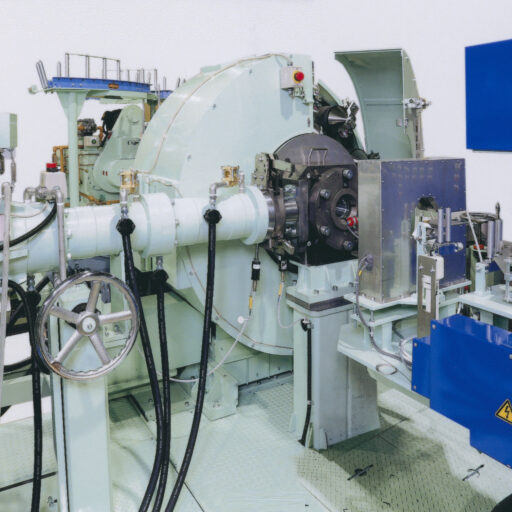

Straighthead / Crosshead

Mainly use straighthead in case of single layer tube or sheet extrusion, use crosshead for coating or multi layer extrusion.

Multi Layer Head

It is effective for rubber material products including complicate shaped sponge-solid and frequent uneven thickness products.

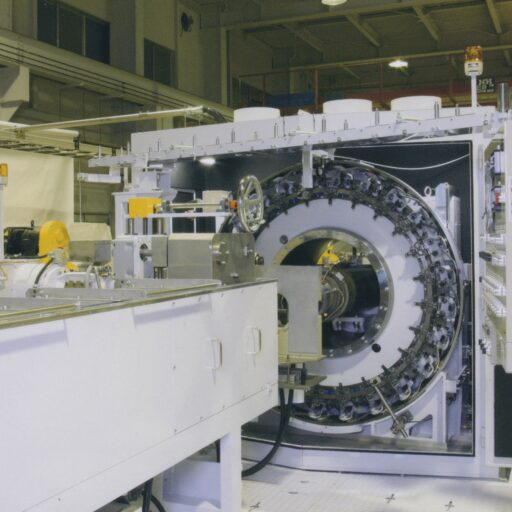

Horizontal Vulcanizer

Unvulcanized rubber products have just been discharged from an extruder will remain deformed when force is applied and will not return to their shape, and will easily tear if pulled.

Therefore, heat is applied to this unvulcanized rubber to cause it to react with the vulcanizing agent and sulfur, increasing the elasticity and strength of the rubber. Through this vulcanization process, rubber tubes and irregularly shaped products are manufactured from the above materials.

Compared to vertical vulcanizer tanks, production is possible at faster line speeds. (Note: Depends on vulcanization conditions and installation space)

Since the height of the equipment is low, it can be installed at the height of a typical factory without the need for building renovation work.

Since work can be done on the floor, maintenance and work can be done easily.

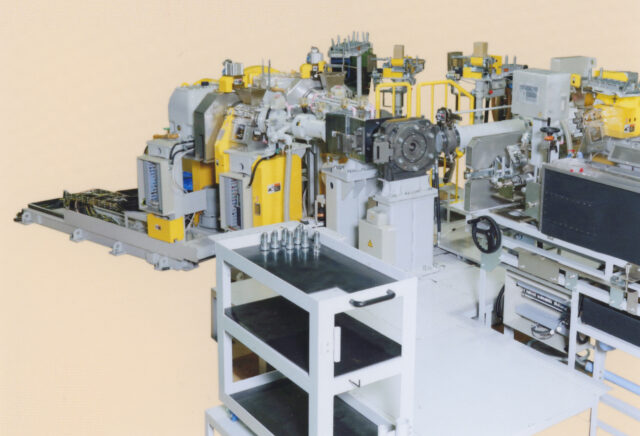

LCM Vulcanizer

- Compared to other methods (UHF, HAV, PCM), it generates less gas and vulcanizes without touching the air, so there is less oxidation and deterioration.

- Since the heat medium is liquid, temperature control is easy.

- The temperature is evenly applied without unevenness to the entire circumference of the work.

- Because it does not come into contact with air, it is also effective for vulcanization using a peroxide (organic peroxide) vulcanizing agent