One-Step Silane Cross-Linking CV Line

シラン 架橋 CVラインSilane Cross-Linking CV Lineワンステップシラン架橋CVラインOne-Step Silane Cross-Linking CV Line1. ワンステップシラン架橋押出機1. One-Step Silane Crosslinking Extruder弊社が開発したシランインジェクションを採用した本押出機はシランカクテル材の吐出バラツキ無く、回転数を上げても リニアに押出機に供給することが出来ます。This extruder, incorporating our proprietary silane injection technology, delivers silane cocktail material with consistent discharge, enabling linear supply to the extruder even at increased rotational speeds.スクリューサイズも150㎜クラスまで対応可能です。Screw sizes up to 150 mm are also supported.2. 高吐出押出機2. High out-put Extruderシース押出機やワンステップ架橋方式以外の絶縁押出機には、特殊形状を用いたスクリューやシリンダーにより、同サイズの汎用押出機に対して、1.5~2倍の吐出量を可能にした高吐出タイプの押出機をお勧めいたします。For insulation extruders other than sheath extruders and one-step crosslinking systems, we recommend high-output extruders. These feature specially shaped screws and cylinders, enabling 1.5 to 2 times the output compared to general-purpose extruders of the same size.押出量アップすることで押出機が1~2ランクサイズダウン出来ますのでレイアウトの検討代が広がり、材料ロスの低減に繋がります。Increasing the extrusion volume allows the extruder to be downsized by one or two grades, expanding layout options and reducing material waste./?p=297/?p=297(本機の詳細はコチラ)(Click here for more details about this unit)3. サブ押出機3. Sub-extruderシース工程用ストライプ押出や絶縁工程用スキン層押出などに使用するため旋回、前後移動、昇降など機能を兼ね備えたサブ押出機も縦型や横型など各サイズを取り揃えています。レイアウトや押出量によりお選びいただけます。We offer sub-extruders with functions such as swiveling, forward/backward movement, and vertical adjustment for applications like strip extrusion for sheath processes and skin layer extrusion for insulation processes. Available in various sizes including vertical and horizontal configurations, they can be selected based on layout and extrusion volume requirements.縦型50mm押出機Vertical-Type 50-mm Extruder横型50mm押出機Horizontal-type 50 mm extruder4. 引取機4. Pickup machineケーブル径、牽引力、引取速度やレイアウトにより、キャタピラタイプやベルトラップキャプスタン方式など豊富なバリエーションから最適機種をご提案いたします。Based on cable diameter, pulling force, retrieval speed, and layout, we offer the optimal model from a wide variety of options, including caterpillar-type and belt-tension capstan systems.キャタピラ引取機Caterpillar typeベルトラップキャプスタン引取機Belt-tension capstan type5. サプライスタンド/巻取機5. Supply Stand/Winderサプライスタンド及び巻取機もレイアウトやドラムサイズにより豊富な機種を取り揃えております。弊社推奨は、市販のタイヤを使用したタイヤ駆動式巻取機でメンテナンス性や操作性に優れており、リピーターの多い製品です。We offer a wide range of supply stands and winders to suit various layouts and drum sizes. Our recommended product is a tire-driven winder using commercially available tires, which excels in maintainability and operability and has a high repeat purchase rate.タイヤ駆動式デュアル巻取機Tire-driven dual winding machine自走式門型巻取機Self-propelled gate type winder吊下げ式門型巻取機Hanging-type gantry winder6. アキュームレーター6. Accumulator滑車溝径φ1500㎜、張力400kgfまでの太物高張力タイプも準備しております。用途に合わせた滑車表面処理をご提案いたします。We also offer heavy-duty high-tension pulleys with a groove diameter of φ1500 mm and a tension capacity up to 400 kgf. We can recommend surface treatments for pulleys tailored to your specific application.7. 制御操作盤7. Control Panelハード、ソフトとも自社設計のため、お客様のご要望に出来る限り副うようインターロックや連動制御など機械設計と一緒になってきめ細やかなシステムプログラムの構築を行っています。Since both the hardware and software are designed in-house, we work together with mechanical design to build detailed system programs, including interlocks and interlocking controls, to meet customer requests as much as possible.遠隔管理や条長制御、張力制御など弊社独自のシステムを取り入れた制御は、オペレーターの負担軽減やロス低減、作業性向上に繋がり、高評価を得ております。Our control system, which incorporates our unique systems such as remote management, length control, and tension control, reduces operator burden, reduces loss, and improves work efficiency, and has been highly evaluated.[条長制御][Length control]予めレシピ画面に登録された製品情報(導体長、製品長、色など)により、カラーフィーダーや色替えバルブに指令信号を出力するとともにライン速を段取り速度まで自動で減速させます。オペレーターが色替え完了確認後、スイッチ1つで生産速度まで自動立ち上げを行います。Based on the product information (conductor length, product length, color, etc.) registered in advance on the recipe screen, a command signal is output to the color feeder and color change valve, and the line speed is automatically reduced to the setup speed. After the operator confirms that the color change is complete, the machine will automatically start up to production speed with a single switch.[張力制御][Tension control]レシピ画面に登録したライン張力に対して、アキュームレーターや引取機部に組み込んだロードセルの実張力データーを基に微調整を行っています。ケーブルの品質向上に繋がります。Fine adjustments are made to the line tension registered on the recipe screen based on the actual tension data of the load cell built into the accumulator and pulling machine. This leads to improved cable quality.

Product Features

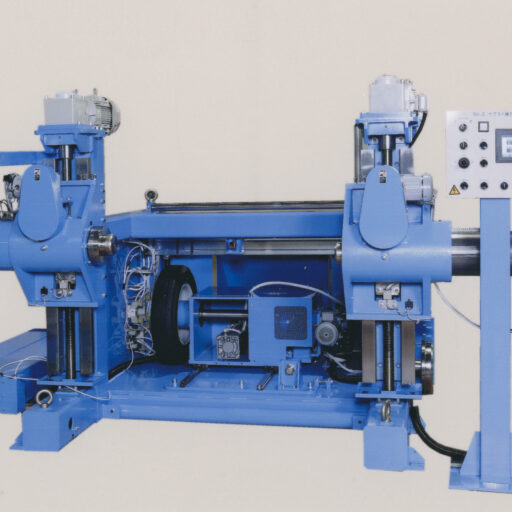

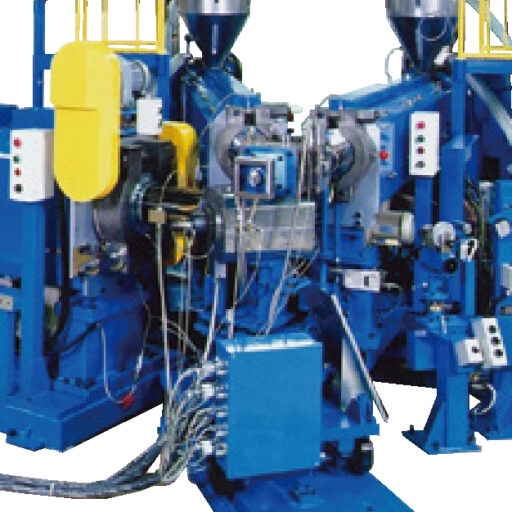

1. One-Step Silane Crosslinking Extruder

This extruder, incorporating our proprietary silane injection technology, delivers silane cocktail material with consistent discharge, enabling linear supply to the extruder even at increased rotational speeds.

Screw sizes up to 150 mm are also supported.

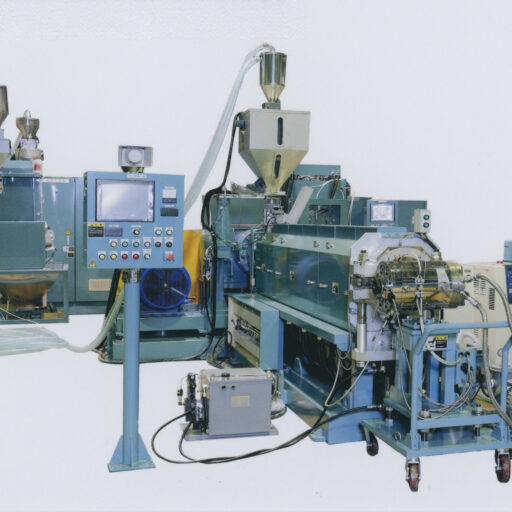

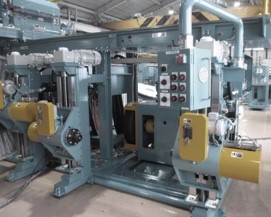

2. High out-put Extruder

For insulation extruders other than sheath extruders and one-step crosslinking systems, we recommend high-output extruders. These feature specially shaped screws and cylinders, enabling 1.5 to 2 times the output compared to general-purpose extruders of the same size.

Increasing the extrusion volume allows the extruder to be downsized by one or two grades, expanding layout options and reducing material waste.

(Click here for more details about this unit)

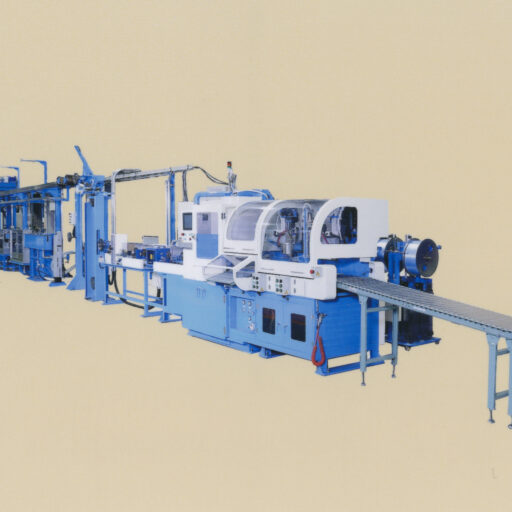

3. Sub-extruder

We offer sub-extruders with functions such as swiveling, forward/backward movement, and vertical adjustment for applications like strip extrusion for sheath processes and skin layer extrusion for insulation processes. Available in various sizes including vertical and horizontal configurations, they can be selected based on layout and extrusion volume requirements.

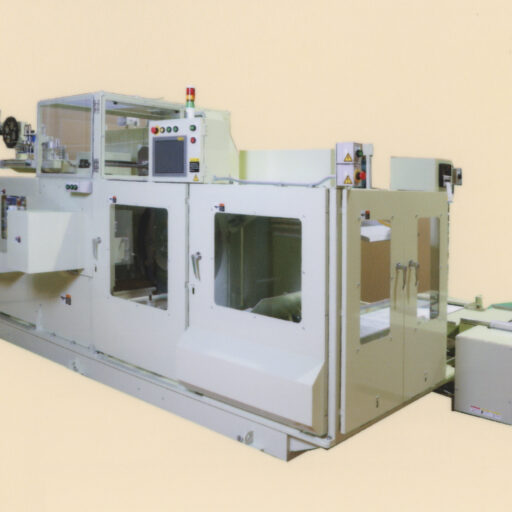

4. Pickup machine

Based on cable diameter, pulling force, retrieval speed, and layout, we offer the optimal model from a wide variety of options, including caterpillar-type and belt-tension capstan systems.

5. Supply Stand/Winder

We offer a wide range of supply stands and winders to suit various layouts and drum sizes. Our recommended product is a tire-driven winder using commercially available tires, which excels in maintainability and operability and has a high repeat purchase rate.

6. Accumulator

We also offer heavy-duty high-tension pulleys with a groove diameter of φ1500 mm and a tension capacity up to 400 kgf. We can recommend surface treatments for pulleys tailored to your specific application.

7. Control Panel

Since both the hardware and software are designed in-house, we work together with mechanical design to build detailed system programs, including interlocks and interlocking controls, to meet customer requests as much as possible.

Our control system, which incorporates our unique systems such as remote management, length control, and tension control, reduces operator burden, reduces loss, and improves work efficiency, and has been highly evaluated.

[Length control]

Based on the product information (conductor length, product length, color, etc.) registered in advance on the recipe screen, a command signal is output to the color feeder and color change valve, and the line speed is automatically reduced to the setup speed. After the operator confirms that the color change is complete, the machine will automatically start up to production speed with a single switch.

[Tension control]

Fine adjustments are made to the line tension registered on the recipe screen based on the actual tension data of the load cell built into the accumulator and pulling machine. This leads to improved cable quality.