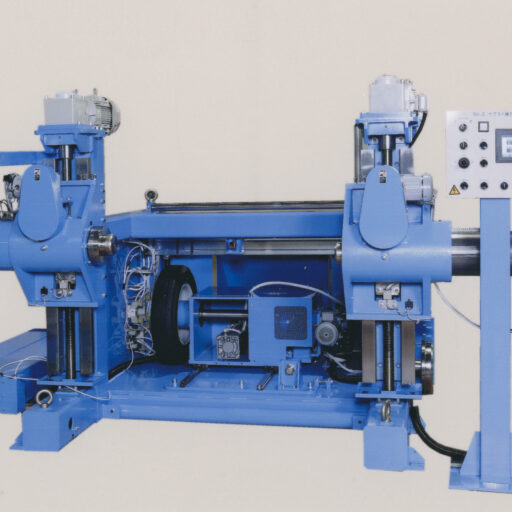

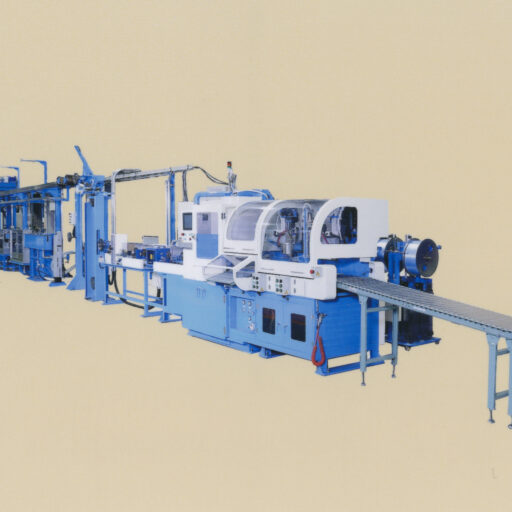

Single Automatic Winder

There is also a bobbin traverse type for wide cables such as flat cables and flat square wires.

Product Features

1.Abundant

A wide variety of models with flange diameter of 300 mm to 900 mm and a full roll weight of 500 kg depending on the application.

Since we (Mitsuba) have both line traverse and bobbin traverse methods, we will propose a winder suitable for the type and characteristics of the cable.

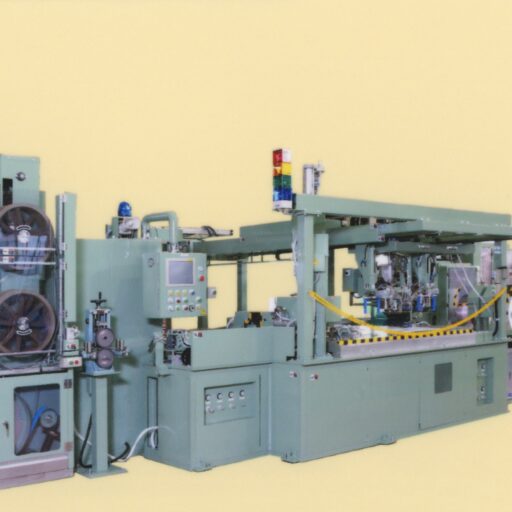

2.Short Setup Time

The electric lifters with servo motor are employed and drum lifting is controlled by selecting drum on the touch panel in the operation panel.

Although there are several drum sizes, setting is done automatically without parts change or adjustment. Work efficiency can be improved.

3.Reduction of Cable Chuck Error

The cable clamp part is designed with our original mechanism to reduce cable dropouts and the problems caused by chuck errors are reduced.

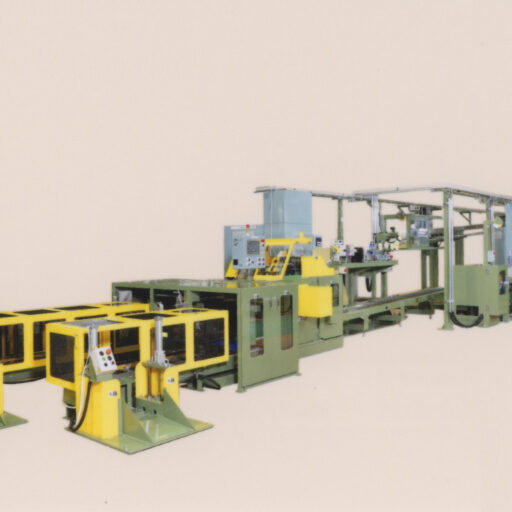

4.Reproducibility of winding shape

By registering the optimum turn position and traverse pitch according to the characteristics of the cable in the polygon recipe on the control panel, you can reproduce the winding shape regardless of the skill of the operator.

5.Variation of drum loading/unloading

A wide variety of drum supply and unloading mechanisms are made to order according to the layout, so installation in a limited space can be considered.

・One of drum stocker has a simple structure that feeds an empty drum to the winder using the tilt without using a motor. The length can be shortened by overlapping drum flange.

It is most suitable for light weight drum because operator supplies drums to the stocker.

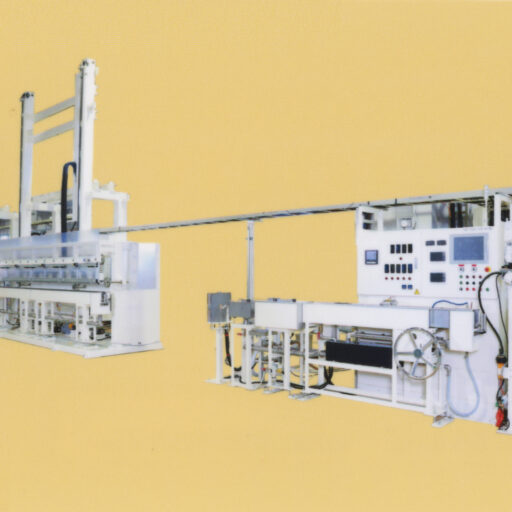

A pit-embedded electric empty drum conveyor suitable for heavy drums. It can also be used as a carry-out conveyor.

・It is possible to increase the number of stocks by making the carry-out conveyor into a double type or carry out defective products on one side. In addition, by adopting a flat conveyor belt and arranging the drums sideways, the conveyor length can be shortened and the rolling of the drum is suppressed to prevent product damage.