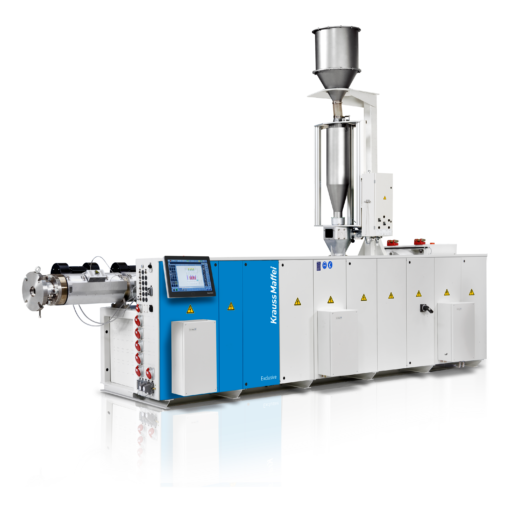

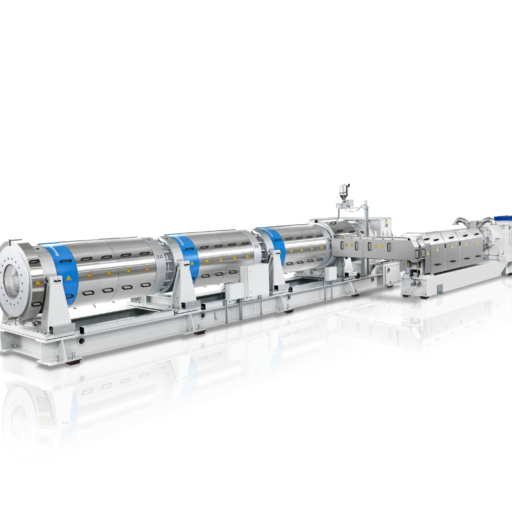

Same direction revolution Biaxial Extruder

The surface of the barrel bore of the ZE-UTX series is directly hardened by means of an innovative fabrication method (special heat treatment process), so the cooling jacket and processing part are close to each other, to achieve superior cooling effects. Further, by combining the extruder with a melt pump, compounding and forming can be carried out in a single process.

Product Features

Cutting-edge biaxial ZE-UTX/UT type is prepared D/d difference ZE-A version and ZE-R version.

As ZE-A version type (D/d = 1.46) can gain optimum torque for selected bulk, provides high discharge rate by high screw torque. It is suitable for high-performance composition, blending, filling, reinforcement, producing masterbatch, powderizing, microparticulate polymer treatment.

ZE-R version type (D/d=1.74) is bigger bulk design, able to obtain longer residence time, suitable for extrusion associated higher torque compare to ZE-A. Then there are features optimum melt condition, low volatileness and low input shear. It is suitable for treating material which extremely high filling degree of filler, blending TPE, reaction, condensing and deaeration treatment.

Since cylinder is modulized, it is possible to optimize in combination with cylinder module of each block by use. By adopted C clamp type cylinder attachment unit enables exchange cylinder module in a short time.

Screw also has wealth of elements tailored to purpose, so we can provide optimum screw design.