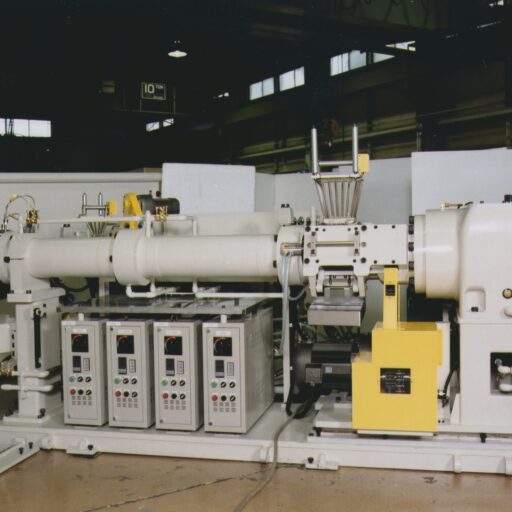

TPX Resin Extruder

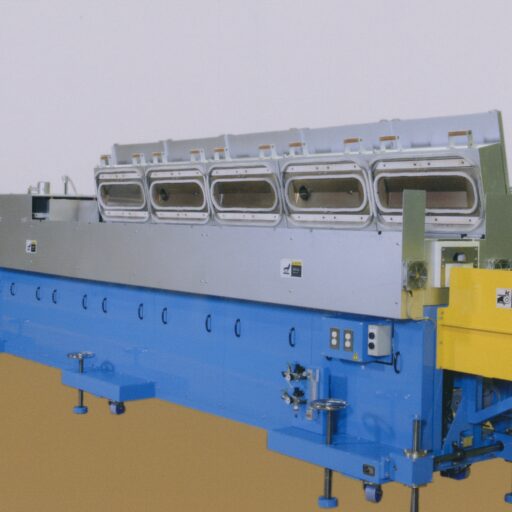

At rubber hose manufacturing sites, taking advantage of its features, it is used as a substitute for lead in many companies and manufacturing sites for sheaths during vulcanization and for mandrel due to recyclability.

At Mitsuba, we've been manufacturing and selling dedicated extruders since TPX® resin launch. At this time, we have developed new, upgraded version.

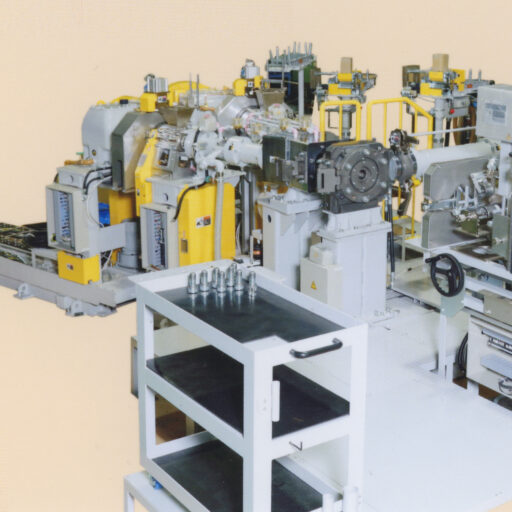

Product Features

1. Low temperature and high discharge extrusion

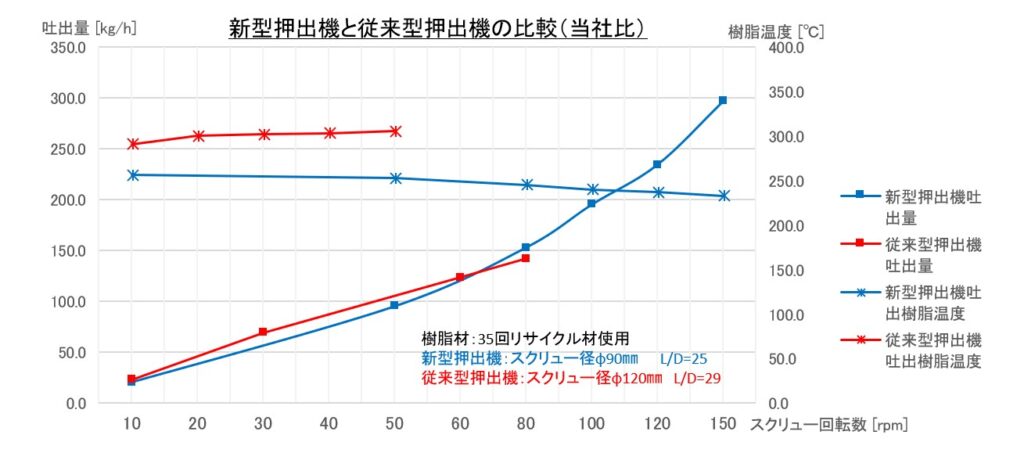

The new extruder adopts a special shape for the groove and screw of the feed liner to prevent the viscosity of the resin from decreasing due to shear heat generation, and the specific extrusion amount from decreasing even in the screw high rotation range, and to make it possible to correspond to a stable discharge rate with the rotation speed.

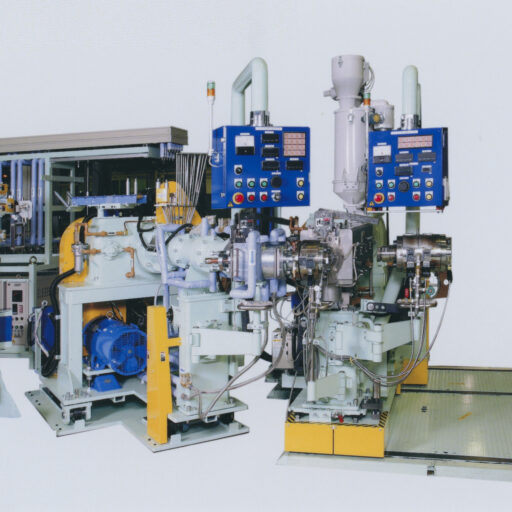

The following graph is comparison of extrusion data between new 90mm extruder and our existing 120mm extruder. According to this graph, new model’s discharge rate is superior to existing one even at same screw rpm, and considering that it can be used in the high rpm range, it can be compensated for conventional extrusion volume by extruder one or two size smaller than existing one.

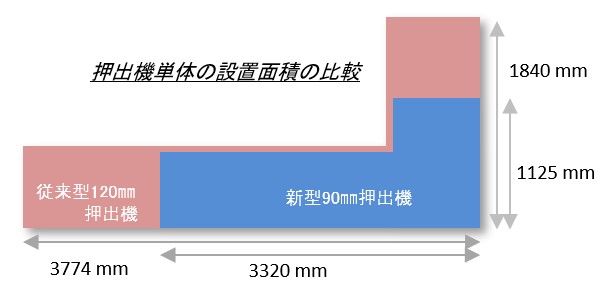

2. Space saving and reduction of material loss

According to the graph in above section, new extruder with downsized screw diameter and L/D compared to the conventional type can compensate for the required extrusion volume, and it leads space saving

In addition, the smaller size reduces the amount of residual material in the cylinder, which contributes to the reduction of material costs.

※50% reuduction of material remaining in cylinder(Compared to our company’s product : by extruder size of chart on the right.)

3. Abundant size variations

New extruders are available in screw diameters from φ50mm to φ150mm, so you can select the type that best suits your extrusion requirements.