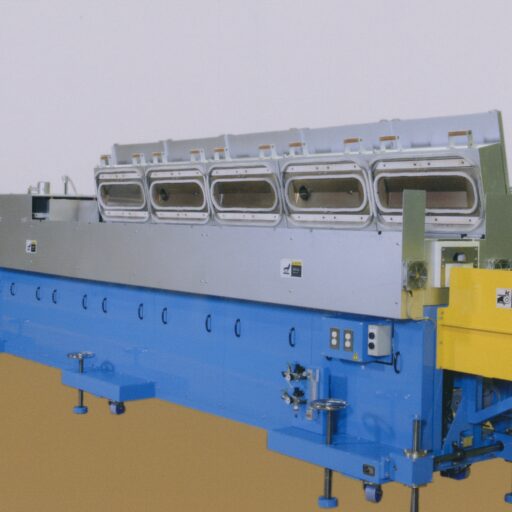

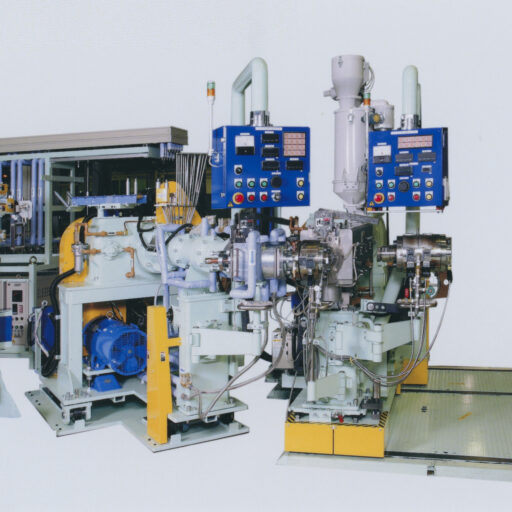

TPX Sheathing line

At rubber cable, tube and hose manufacturing site, TPX resin used as sheaths during vulcanization and mandrels. TPX sheaths keep the product’s outer diameter uniform during vulcanization and make its outer surface glossy. TPX mandrels makes accuracy of product’s inner diameter high.

In addition, TPX resin have a high releasability and recyclability, so the mandrels and sheaths are easy to remove from product and extrude as mandrels and sheaths again. So it reduce waste resin and effort at manufacturing site.

In addition, TPX resin have a high releasability and recyclability, so the mandrels and sheaths are easy to remove from product and extrude as mandrels and sheaths again. So it reduce waste resin and effort at manufacturing site.

Product Features

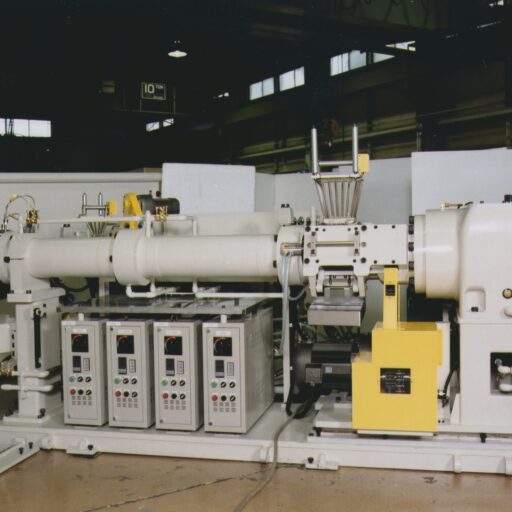

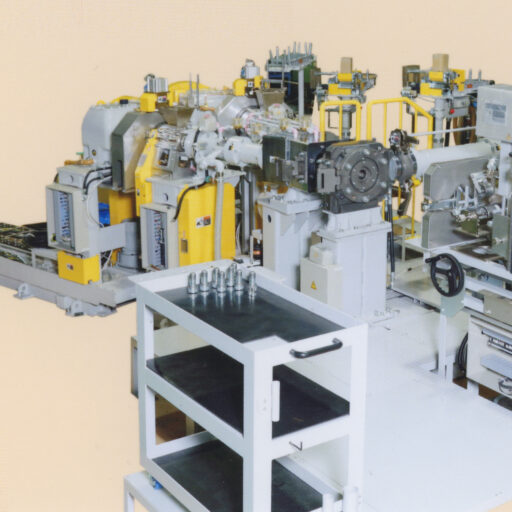

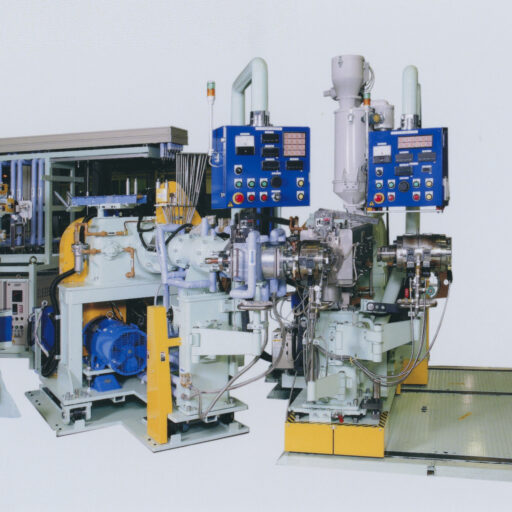

TPX extruder

TPX® resin (trade name/ generic name polymethylpentene of Mitsui Chemicals, Inc.) is a polyolefin resin with excellent heat resistance, mold releasability, and transparency.

At rubber hose manufacturing sites, taking advantage of its features, it is used as a substitute for lead in many companies and manufacturing sites for sheaths during vulcanization and for mandrel due to recyclability.

The new extruder adopts a special shape for the groove and screw of the feed liner and to make it possible to correspond to a stable discharge rate with the rotation speed.

The new extruder has a screw diameter of φ50 mm to φ150 mm, so you can choose according to the required extrusion amount.