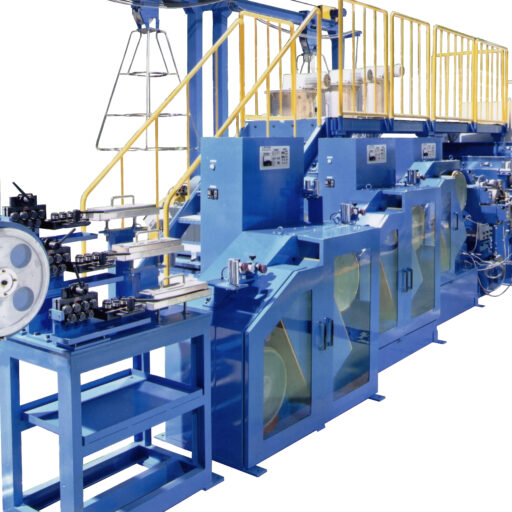

High Discharge Type Resin Extruder

Product Features

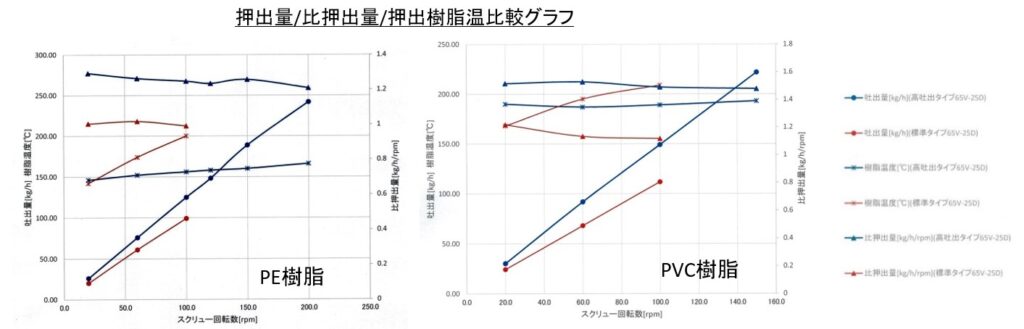

1.High throughput / low temperature extrusion

As the following graph shows, (Compared to our company’s products)

In addition, the effect of shear heating due to screw rotation is minimal, and since the screw can be used in a high rotation range, the total extrusion rate can be expected to be nearly twice that of the total extrusion rate.

※ There are differences depend on resin materials, extrusion size, extrusion pressure.

2.Increase production speed

Within the limited installation space of the extruder, it has the same throughput as a large extruder of one size-up or more, which leads to an improvement in production speed.

If you are considering increasing production speed on an existing line, it is possible to update the existing extruder in the same space as the existing extruder. (See comparison table with general-purpose extruder below)

3. Material loss reduction.

The ability to reduce the size of the extruder by one or two sizes with the same extrusion volume reduces the amount of material remaining in the cylinder when changing materials or colors, which is expected to improve the running cost. (See the comparison table with general-purpose extruders below.)

4. Space saving

The size of the extruder can be reduced, which allows for a more flexible layout for two-layer and three-layer extrusion, and the joints can be shortened, which leads to improved cleanability and resin burns. (See comparison table with general-purpose extruder below)

5. Maintainability

Since basically using machinery and electrical components made in Japan, there is no interfere about parts procurement in case of breakdown. In addition, due to hardware and software are in-house design, and customers can choose PLCs and other components made by domestic manufacturers with which customers are familiar, easy to link with lines of your factory.

6.Abundant size variations

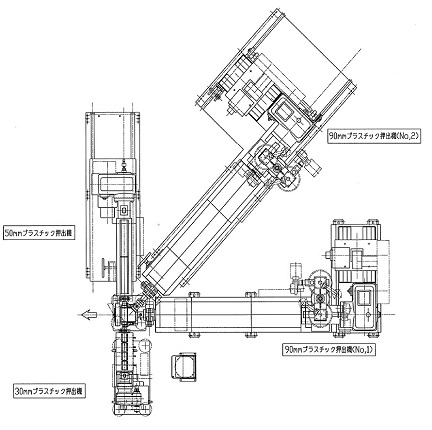

We have a variety of screw diameters from φ50mm to φ150mm, so we can offer a wide range of sizes to suit your extrusion volume and application.

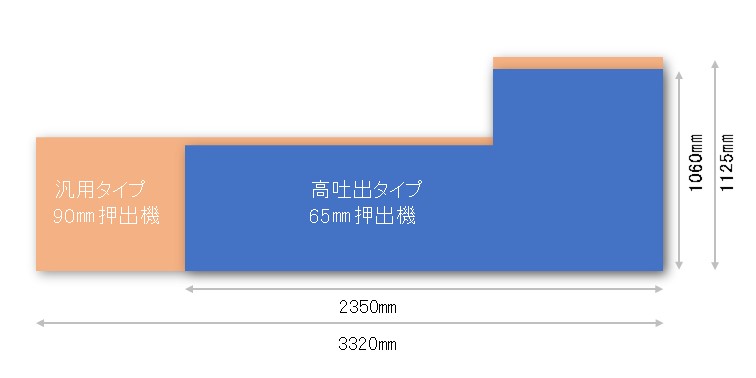

Comparison to general-purpose extruder

The table below shows a comparison between a general-purpose 90 mm plastic extruder (L/D=25) and a high-discharge type 65 mm plastic extruder with the same extrusion capacity. (compared to ours)

| 高吐出タイプ押出機 スクリュー径φ65㎜,L/D=25 | 汎用タイプ押出機 スクリュー径φ90㎜,L/D=25 | |

| Installation space (*1) | Length 2530 mm x Width 1060 mm | Length 3320mm×Width 1125mm |

| Resin remaining in cylinder | 1.85kg | 3.83kg |

| シリンダーヒーター昇温時 消費電力(※2) | 7.3kWh | 18.7kWh |

(※2)設定温度200℃昇温までの消費電力です。(シリンダー温調回路数:90㎜押出機5回路、65㎜押出機4回路)